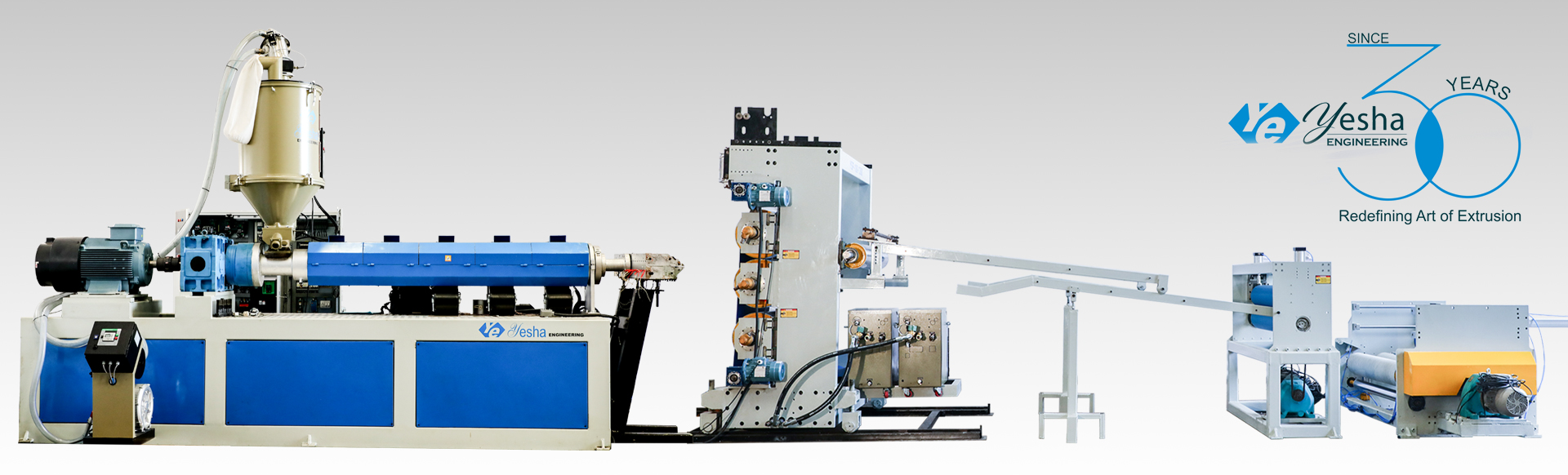

Advanced Cable Tile Extrusion Machine for PE/PVC/PP Cable Covers

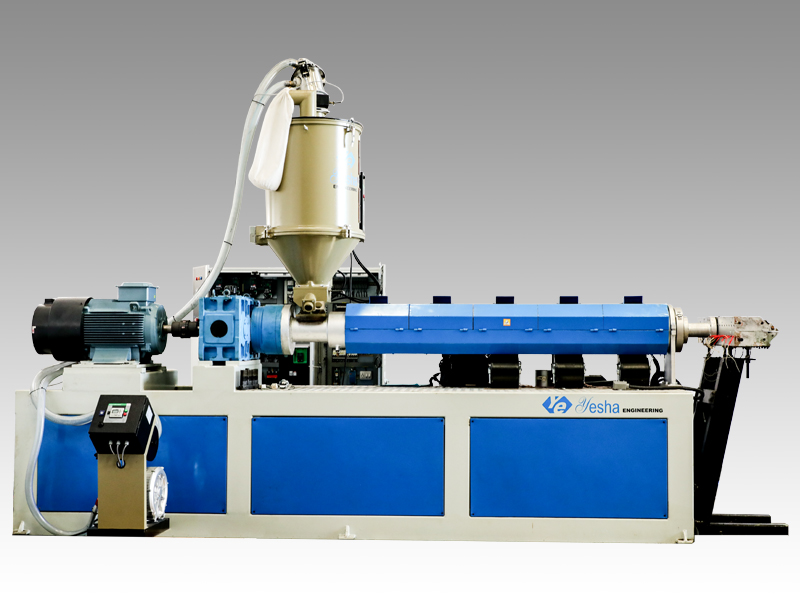

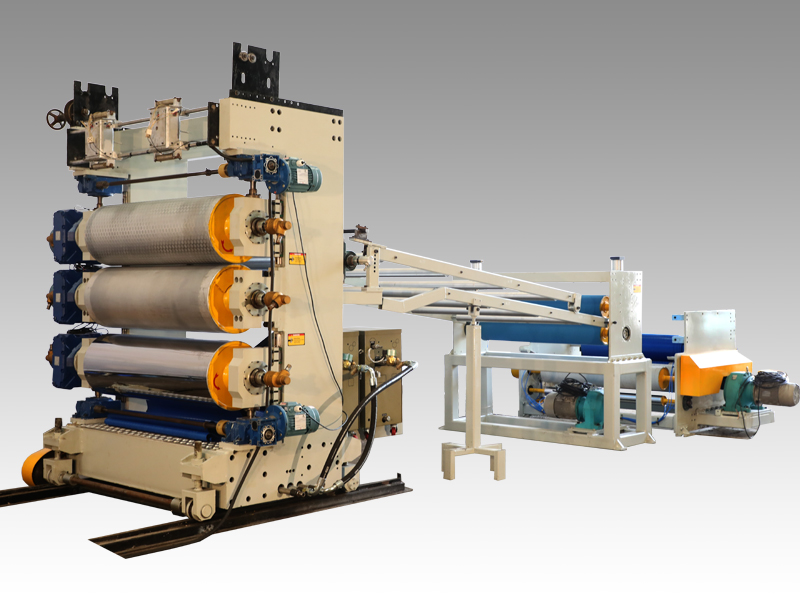

We are a prominent Cable Tile Extrusion Machine manufacturer of fully automatic, high-capacity sheet extrusion lines for underground cable protection cover production. Our Cable Tile Sheet Plant is optimized for reliability, accuracy, and efficiency for the manufacture of PP, PE, PVC, PET, and other thermoplastic cable protection boards.

Employing sophisticated automation and energy-efficient technology, our extrusion lines possess the flexibility to process single-layer and multi-layer plastic sheets of differing thicknesses and widths. These sheets find widespread application as plastic cable protection covers, an essential element in infrastructure, energy, and telecommunications industries, to protect underground cables and pipes.

Core Machine Capabilities & Specifications

Our Cable Tile Extrusion Line is designed to be versatile, with broad material compatibility and adjustable outputs to suit your production requirements.

Technical Specifications:

- Sheet Thickness Range: 0.1 mm to 30 mm

- Sheet Width Range: up to 2800 mm (Boards up to 3600 mm available)

- Material Compatibility: PVC, PP, PE, HDPE, PET, PC, ABS, PS, HIPS

- Production Output: up to 800 kg/h

- Automation: Fully automatic PLC control system (Siemens/ABB/Schneider)

- Custom Lengths: According to client requirements

- Optional Laminated Warning Tape: For added cable identification and safety

Features of Our Cable Tile Extrusion Machine

Wide Range of Materials

Our extrusion line supports multiple polymers such as PP, PE, PVC, PET, ABS, and more, making it suitable for diverse applications. Whether you’re producing heavy-duty industrial sheets or flexible lightweight covers, the machine delivers consistently high quality.

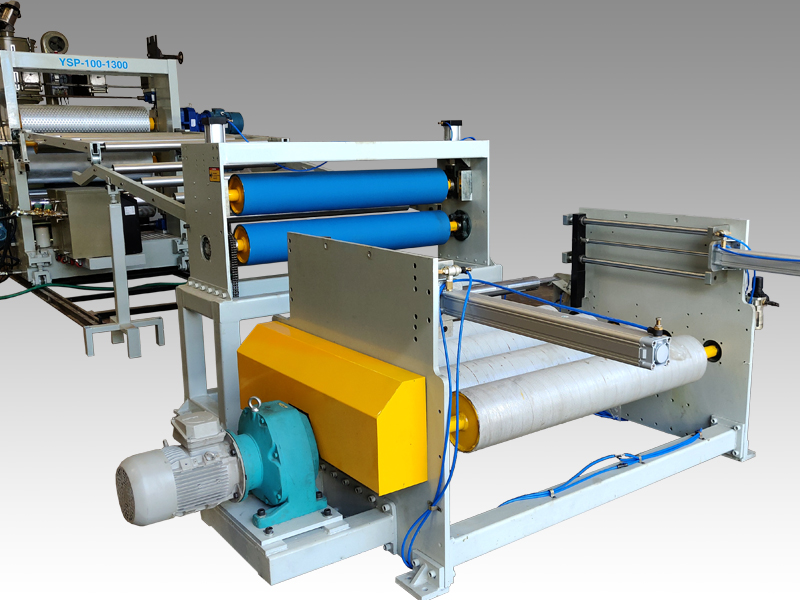

Modular Configuration for Sheet and Board Production

This machine has the ability to cut both thin sheets (0.1mm) and heavy-duty boards (max. 40mm). The board width can be as much as 3600 mm, making it commercially suitable as well as industrially applicable for cable cover solutions.

Optimized Electrical and Control Systems

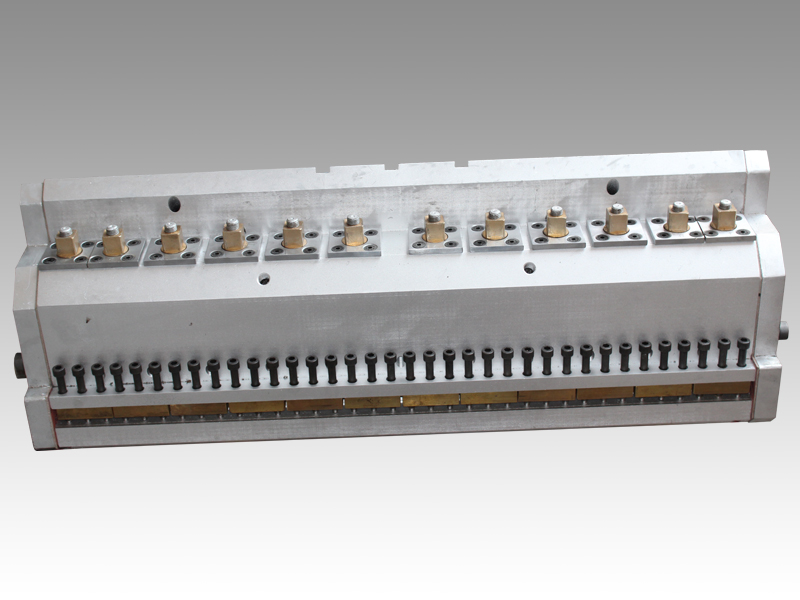

Fitted with:

- Siemens motors

- ABB inverters

- Schneider contactors

- Simple-to-use PLC control system

The line has the capability of real-time monitoring, accurate speed/temperature adjustment, and fault diagnostics, making it an Automatic Cable Extrusion Machine suited for any contemporary facility.

Energy Efficient & Low Waste Design

Our uniquely designed screw and barrel systems, as well as power-efficient components, lead to:

- Less power consumption

- Less raw material wastage

- Improved sheet uniformity and strength

Integrated Warning Tape Lamination

The extrusion line accommodates lamination of pre-printed colored warning tapes onto the top surface of the cable tile sheet, providing a high-visibility protective layer for underground cables.

Applications of Cable Tile Sheets

Our Cable Tile Extrusion Machine is utilized to produce plastic cable protection covers, which are referred to as cable tiles or protection sheets for underground cables. These are necessary for:

- Electrical and High Voltage Cable Protection

- Fiber Optic and Communication Cable Shielding

- Pipeline and Gas Line Protection

- Telecommunication Infrastructure Projects

- Energy and Utility Trenching

- Heavy-Duty Warning Layer Installation

Constructed from recycled polypropylene or polyethylene, they are very light yet highly resistant, thus suitable for long-term installation and maintenance-free requirements.

Advantages of Cable Protection Sheets

- Visual Identification: With embedded warning tape, they provide an early visual indication for excavation work.

- Impact Resistance: Constructed to be resistant to mechanical shocks and weight pressure from soil or construction.

- Chemical Resistance: Highly corrosion, acid-resistant, and environment-resistant.

- Eco-Friendly: Produced from recycled plastics, the sheets promote initiatives for sustainability.

- Cost-Effective: Averts the expense of replacement cables by avoiding damage in the first instance.

Why Select Us as Your Cable Extruder Manufacturer?

Being an experienced Cable Extruder Manufacturer, we specialize in providing machines that address the changing requirements of the cable protection business. Ranging from the Wire and Cable Extruder sector to Sheet Extrusion for underground protection systems, our machinery is worldwide renowned for its reliability, rate, and accuracy.

In addition to providing excellent post-installation support, machine commissioning, training, and technical support, we ensure success for your business in the long run.

Get Started with a Reliable Cable Tile Extrusion Solution

Whatever your business – utility services provider, infrastructure developer, or plastic products manufacturer – our Cable Tile Extrusion Machine provides industry-leading performance, reliability, and customizability.

Our Clientele