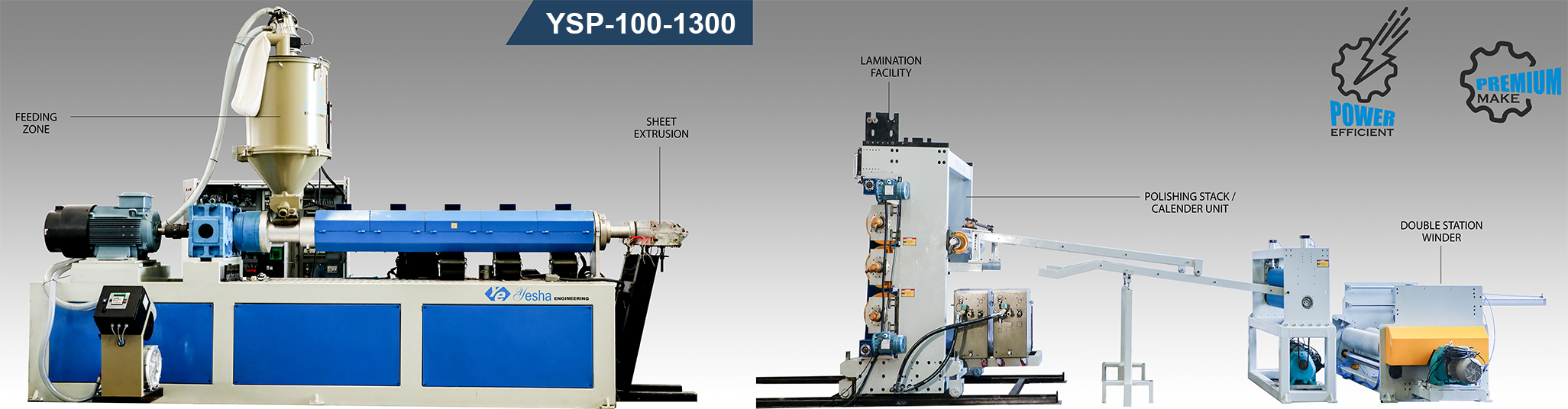

PVC Insulating Floor Matt Extrusion Line

PVC Anti-Slip Electrical insulating Mat Extruder Machine

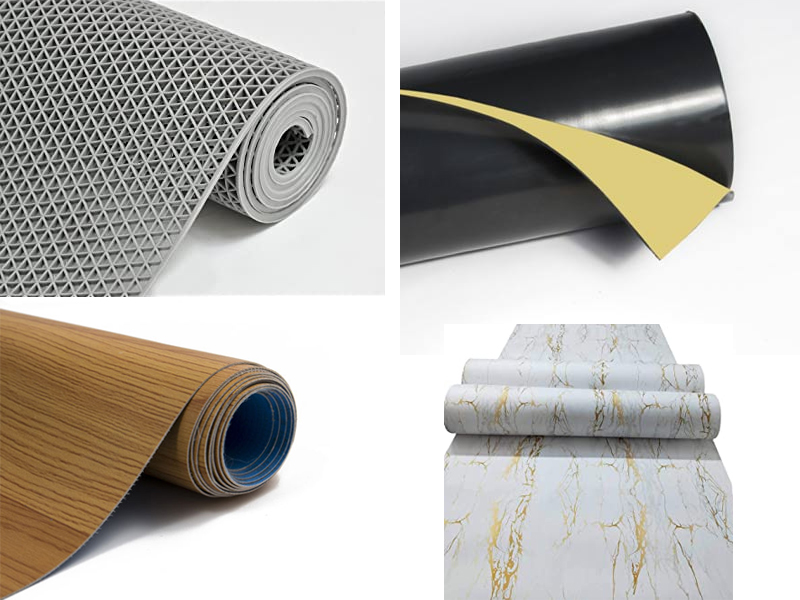

PVC Floor Mat is a kind of calendaring product wiith different back shapes. such like pane shape, tooth shape, strip shape, dot shape, diamond shape etc. The mat have the features of anti-skid, acid and alkali-resistant, anti-UV, high tempetature-resistant, cold-resistant etc. The mat we tested is with good formula, make it very comfort, have a moderate softness. The machine also can compound with the carpet, non-woven fabrics, wich is mainlyused in the door, car, batchroom, hotels, airports, restaurant, holiday resort and many other public places.

Producttion Flow:

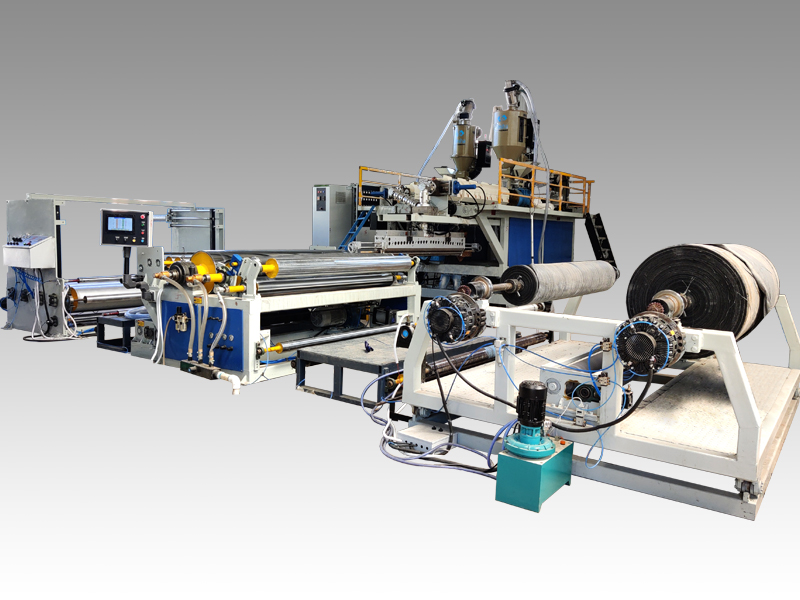

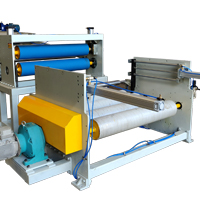

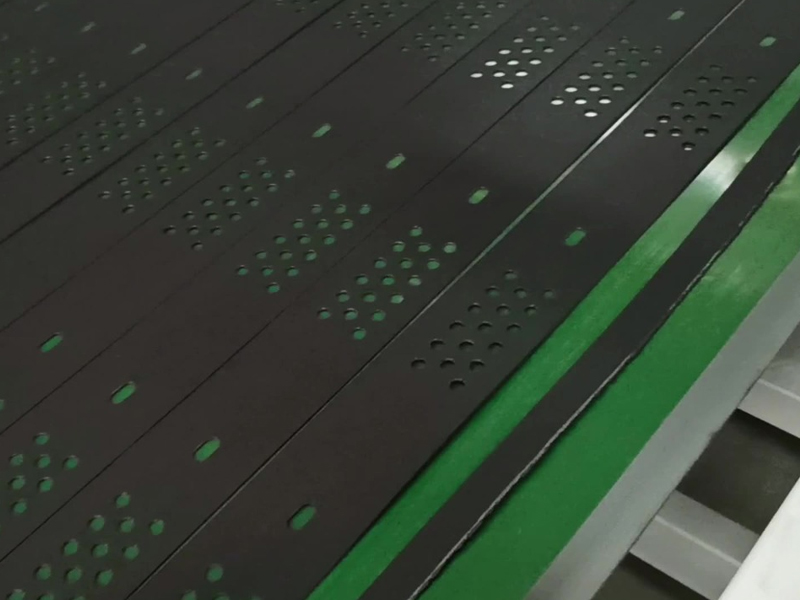

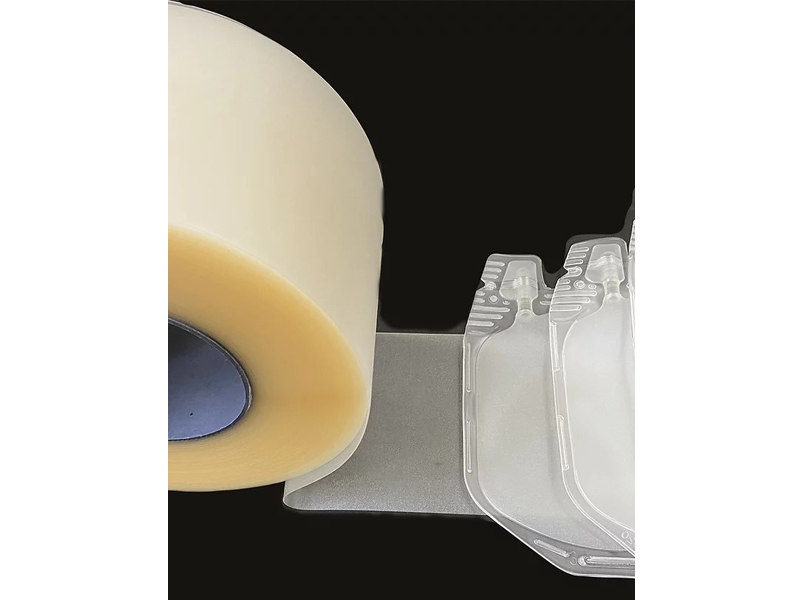

Coin mat of similar single layer type: Maretials mixing–Automatic Feeding into extruder–Extruder melt–Filter–Extrusion Die–Calender forming unit–Film lamination-Cooling frame-Trimming and pulling–Winding.

- Material : PVC GRANULES

- Product thickness : 0.5-3mm

- Product width : 1220mm,2000mm

- Output : 300-350 kg/h

- Line speed : 1-3 m/min

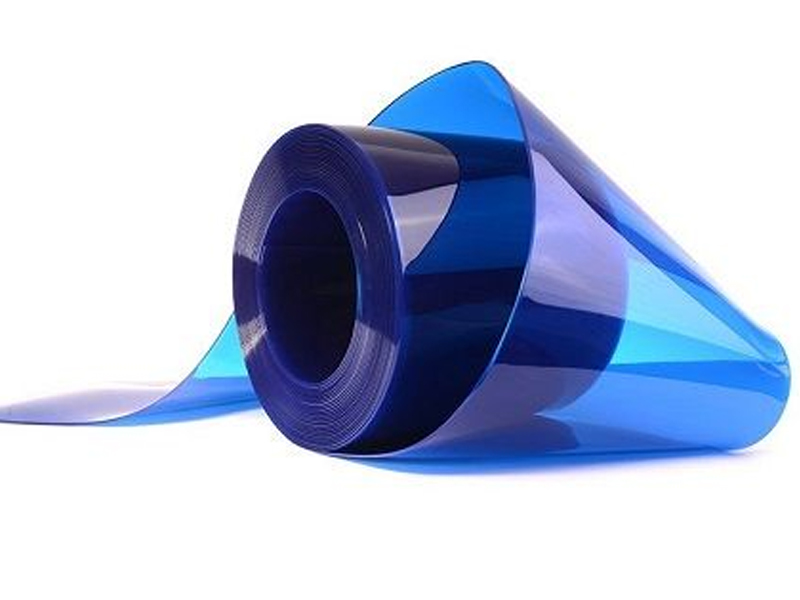

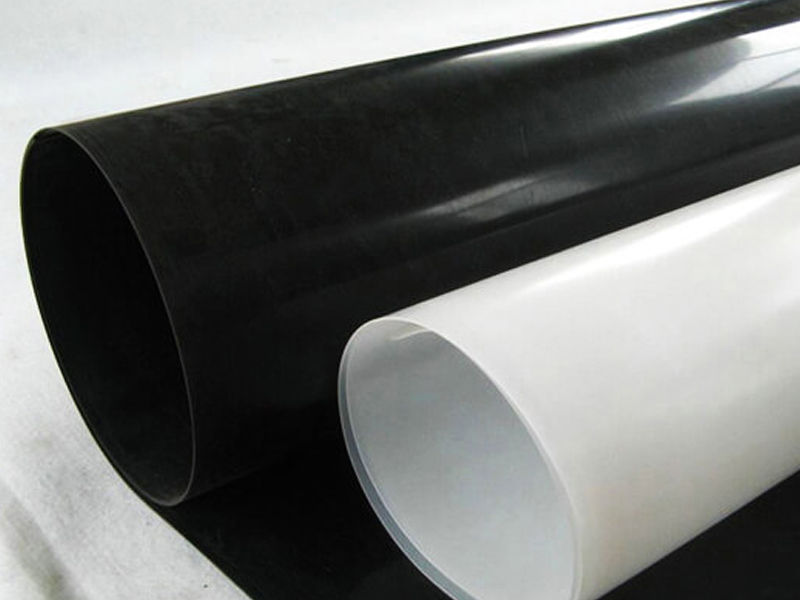

The PVC Sheet/board are widely used in the field of environmental-protection, chemical industry, anti-corrosion, advertisement, architecture, heat preservation, etc.

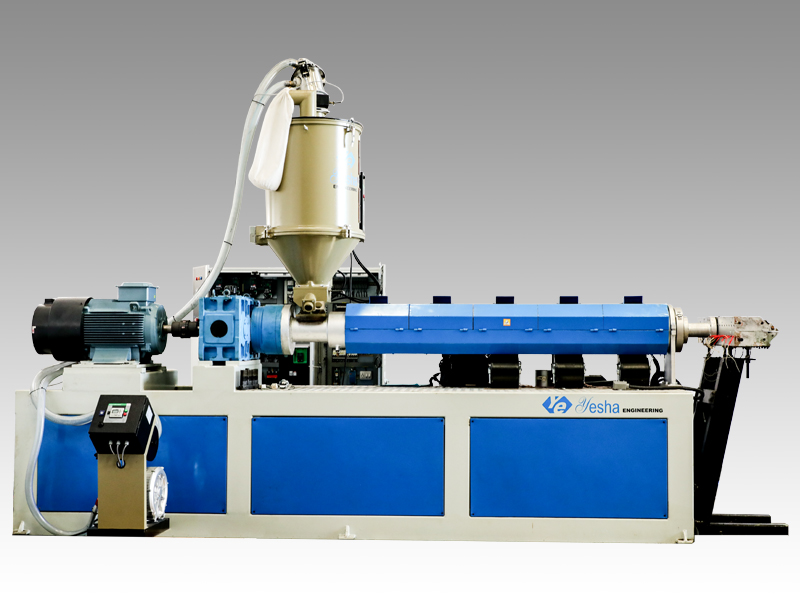

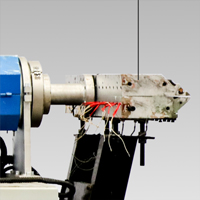

This line has the feature of compact structure, high performance. After special design, screw and barrel has the features of uniform plasticization, stable extrusion capacity, high output, long service time. fan cooling and precision temperature control system provided. calander can adjust the sheet shape and keep product in good situation by precision design. cutting machine has meter counting device, and cut the sheet in righ with no error.

Features

We provide Hopper loader-feeder & dryer for round-the-clock production with less men power.

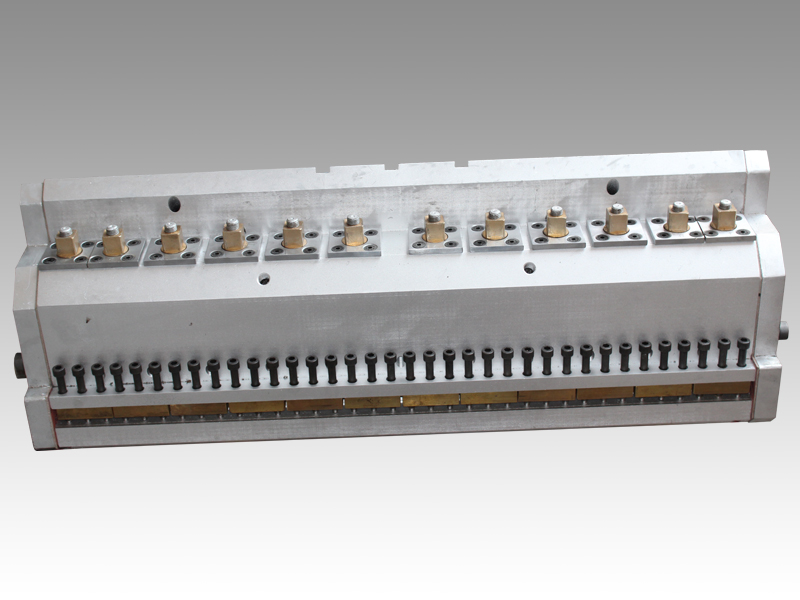

Our precise manufacturing & supreme quality gets effective control over mold for smooth production.

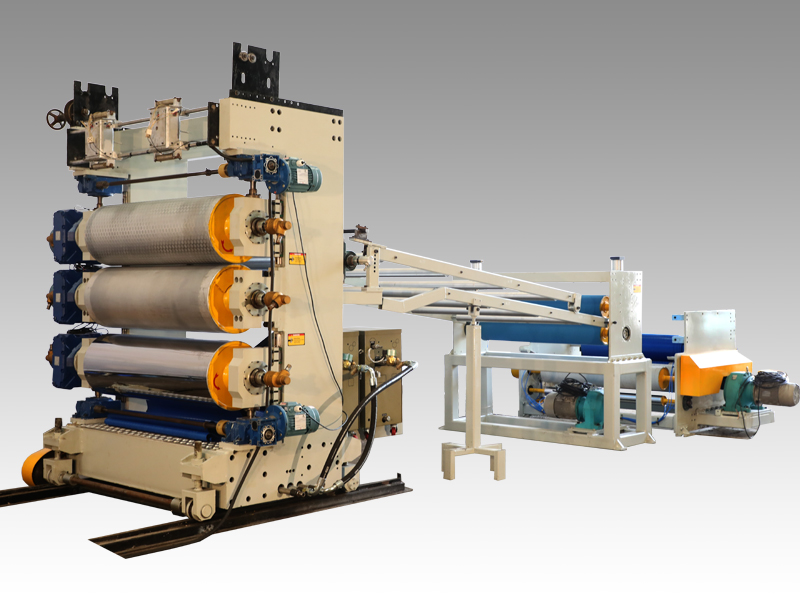

This mechanism is provided for coating addisive layer of sheet/Texture/protection/logo etc.

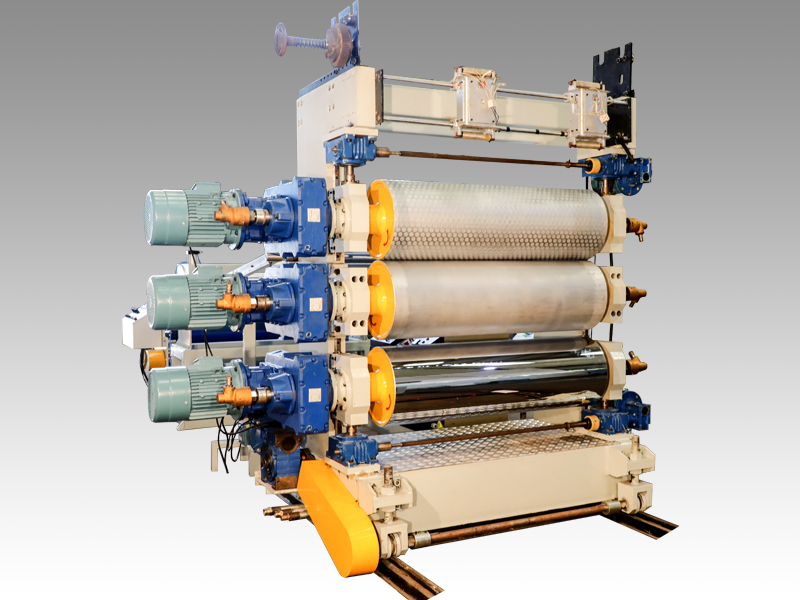

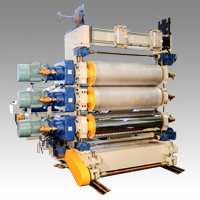

Finishing product & textured design is embossed from this unit , Also to maintain uniform gauge of sheet.

This unit is equipped with AI to cut length given in PLC & to wind the sheet, dual station facility for smooth operations.

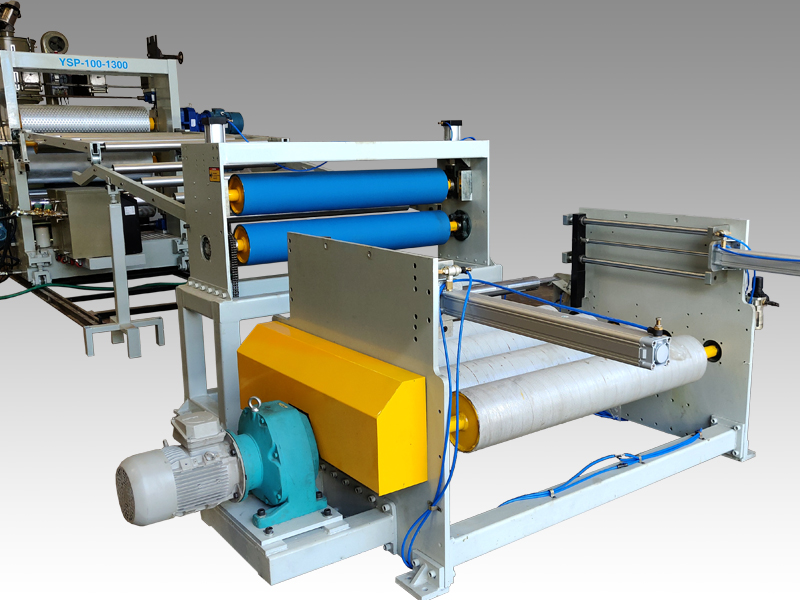

Two super finish silicon-rubber roll are used to pull the sheet/

Solution For Extrusion IndustryWe believe in Quality

Commercial floorings, Waterproofing, Insulation/isolation, Surface Protection, Decorative films, High barrier sheets, Roofing/wall body, Construction material.

Key Features

- Commercial Floorings

- Waterproofing

- Insulation/isolation

- Surface Protection

- Decorative films

- High barrier sheets

- Roofing/wall body

- Construction material

Our Clientele