Chemical Tank Extrusion Machine | Durable and Efficient Tank

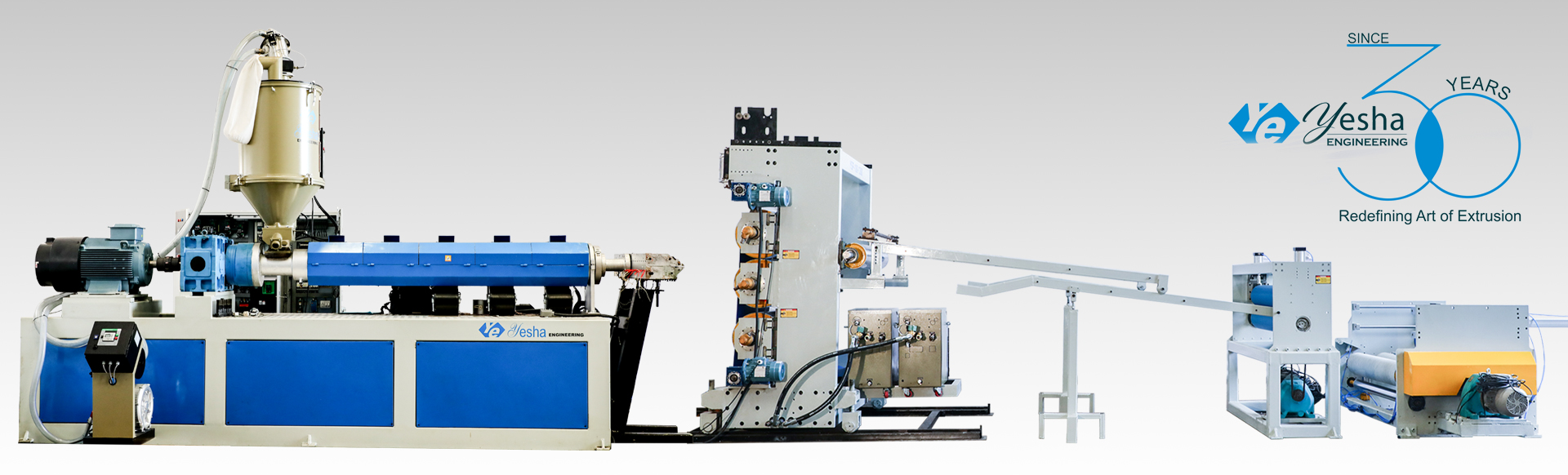

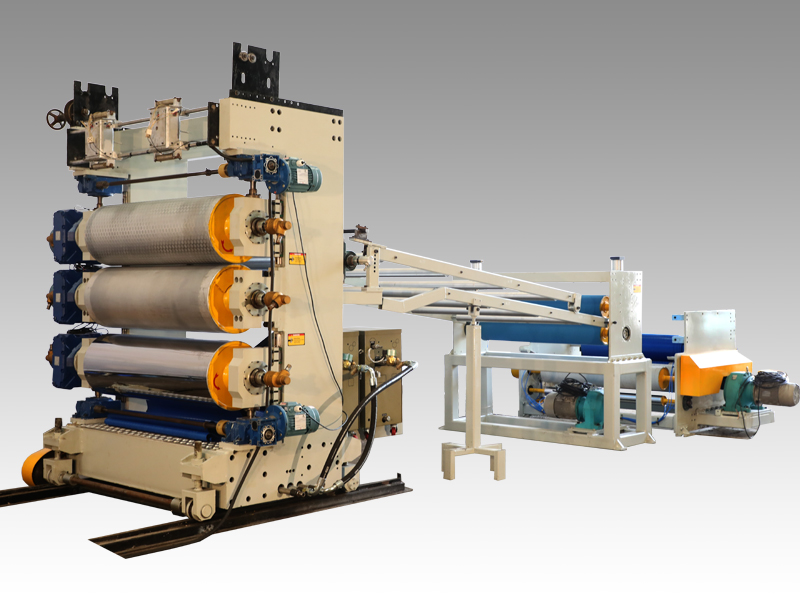

About Our Spiral Chemical Tank Extrusion Line

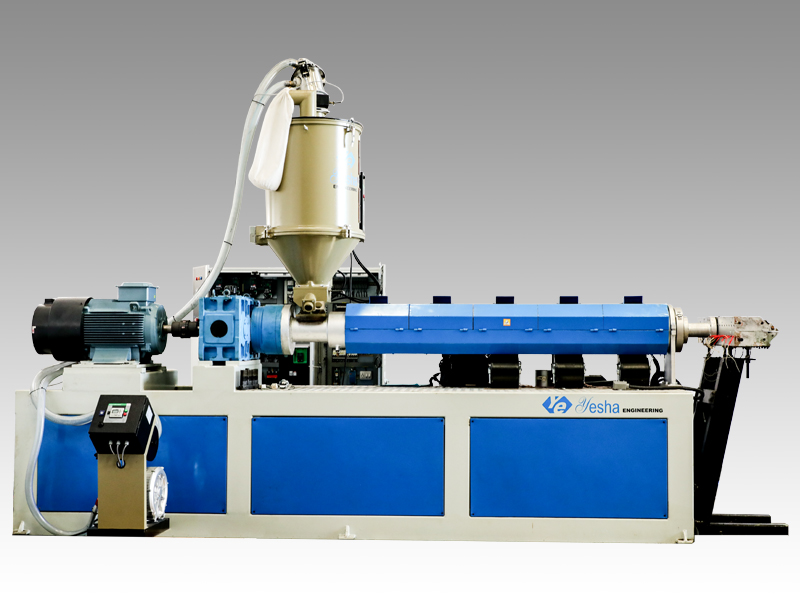

We are experts in the manufacture and design of high-end chemical tank extrusion machines with spiral winding technology. Our HDPE/PP Spiral Tank Machines are designed to produce high-strength, corrosion-proof chemical tanks with adjustable wall thicknesses and extra-large diameters. Equipped with advanced extrusion accuracy, our machines provide a dependable storage solution for chemicals, gases, and industrial fluids.

Being a reliable Plastic Extruder Manufacturer, we combine smart automation, high-output extrusion technology, and modular design, resulting in our tank manufacturing systems being very flexible, efficient, and safe for heavy-duty usage.

Machine Overview – Spiral Chemical Tank Production Line

Our Extrusion Machine has the latest spiral winding technology to produce tanks with optimal structural integrity, impermeable design, and chemical resistance in the long term. The extrusion line is well-suited for thermoplastic materials such as HDPE, PP, and PVDF and can find applications in various industrial processes.

Key Technical Specifications:

- Mould Diameters: Between 600 mm and 4500 mm

- Tank Length Capacity: 6 meters maximum

- Maximum Wall Thickness: 120 mm

- Production Rate: 300–600 kg/h

- Material Compatibility: HDPE, PP, PVDF

- Applications: Chemical storage tanks, process tanks, scrubbers, scrubbing columns, etc.

Key Features of the Spiral Tank Extrusion Line

Spiral Winding Technology for High Strength

The device employs spiral winding to construct tank walls in layers. This technique not only allows for a wall thickness of more than 100 mm, but also eliminates internal tension so that there is no structural stress or deformation with time. This makes the tanks tough, shock-resistant, and chemically stable.

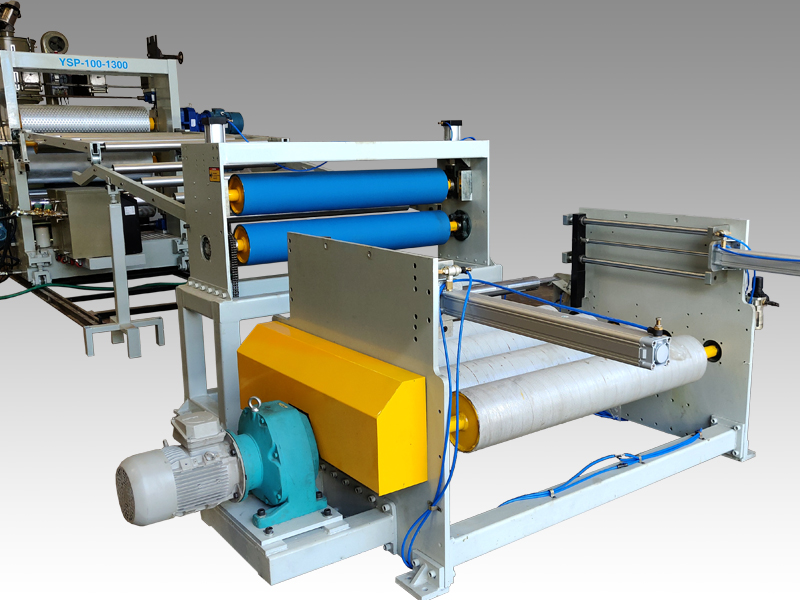

Variable Wall Thickness – Material Efficiency

Our system supports dynamic adjustment of wall thickness based on tank height and application needs. This maximized material distribution minimizes unnecessary use and maximizes structural integrity where it is most necessary.

Leakproof and Durable Welds

The ends and tops of the tanks are welded by an automatic welding station, providing leak-free connections and 100% joint seamlessness. This is important for sectors working with aggressive chemicals, acids, or gases.

Fully Automated Operation

With built-in PLC control systems, the extrusion is automated from material feeding and melting to winding and welding. Easy monitoring and parameter adjustment for optimal performance and safety are facilitated by the operators.

High Output Performance

It has an output capacity of 600 kg/h. The machine is suitable for high-volume production facilities. The build quality, according to Plastic Extruder Manufacturer standards, guarantees continuous use with low downtime.

Applications

Our extrusion line is suitable for manufacturing various types of tanks and components for industrial and chemical sectors:

- Chemical Storage Tanks

- Neutralization and Process Tanks

- Fume Scrubbers and Scrubbing Columns

- Spray Towers

- Large-Diameter Pipes and Chambers

The tanks produced are widely used in industries such as chemical processing, pharmaceuticals, wastewater treatment, mining, agriculture, and semiconductor manufacturing.

Material Compatibility

Our Extrusion Machine is compatible with multiple materials:

- HDPE (High-Density Polyethylene): Excellent for corrosion resistance and flexibility.

- PP (Polypropylene): Resistant to rigidity, heat stability, and chemicals.

- PVDF (Polyvinylidene Fluoride): Ideal for corrosive or high-purity chemical environments.

These plastics, when melted in our high-precision extruders of high precision, produce long-lasting, secure, and compliance-inspecting chemical tanks.

Why Choose Our Tank Extrusion Line?

Reputable Plastic Extruder Maker

Being a leading Silicone Extrusion Machine and PVC Pipe Extrusion Machine manufacturer, we have decades of expertise in customized extrusion line engineering. Our equipment is utilized worldwide in critical industry sectors.

High Engineering & Longevity

From frame design to control systems, each and every element is constructed to sustain extended use, minimal maintenance, and maximum production.

Sophisticated Automation

Our PLC-based smart systems power our machines, providing you with complete control through real-time diagnostics, alarms, and adjustable speed/temperature profiles.

Scalable & Customizable

From tank capacity, material type, output rate, to installation space limitations, we can customize the extrusion line to suit your production requirements.

FAQs

Q1: What is a chemical tank extrusion machine used for?

It is employed to make large, spiral-wound plastic tanks for chemical storage or processing or other industrial liquids and gases.

Q2: What materials can be processed with this machine?

The system accommodates HDPE, PP, and PVDF, which are suited best by their chemical and mechanical resistance.

Q3: Is this machine capable of producing tanks of varying sizes?

Yes, our extrusion machine accommodates moulds from 600 mm to 4500 mm in diameter and up to 6 meters in length.

Q4: Is the welding manual?

No, welding at the top and bottom is completely automatic to provide uniform weld strength and prevent leaks.

Q5: What are the options for wall thickness?

The system can extrude tank walls up to 120 mm thick, adjustable according to specifications.

Q6: Is it possible to use this line to produce PVC pipes or any other extruded items?

Although we specifically make this line for tanks, we also produce PVC Pipe Extrusion Machines and Top Silicone Extrusion Machines for other plastic items.

Q7: Do you provide technical training and installation?

Yes, we offer on-site installation, operator training, and technical support after the sale.

Get in Touch with Us

Take your industrial tank manufacturing to the next level with our Extrusion Machine, designed for strength, safety, and efficiency. As a plastic products manufacturer, chemical distributor, or industrial equipment supplier, we bring you the technology to drive your growth.

Our Clientele