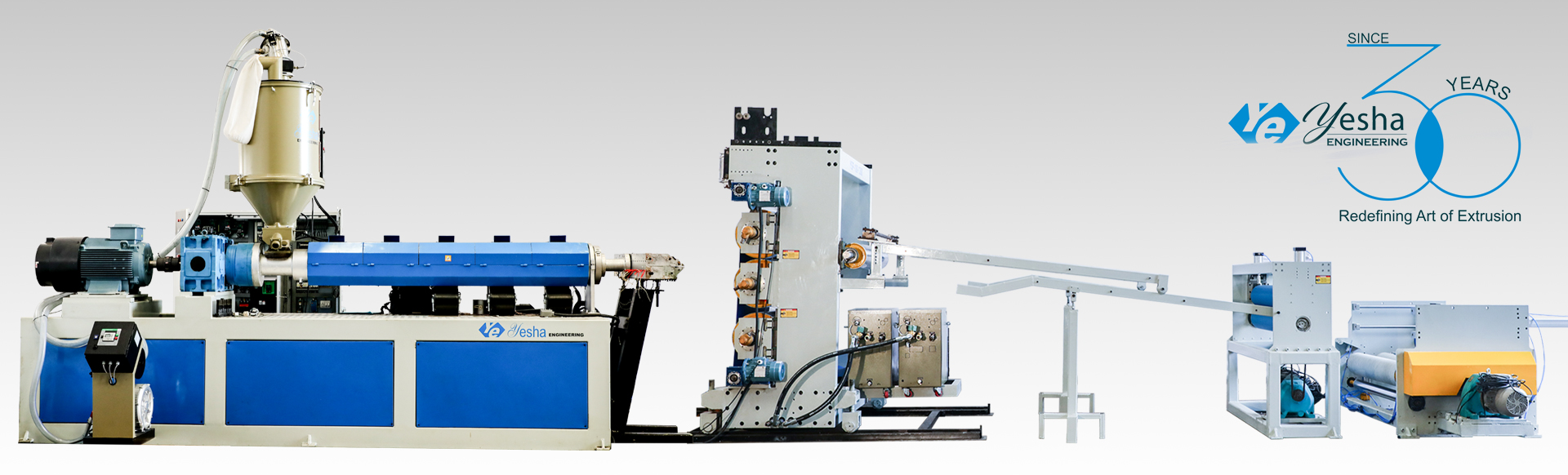

Cable Title Extrusion Machine for HDPE Dimple Drainage Sheet Production

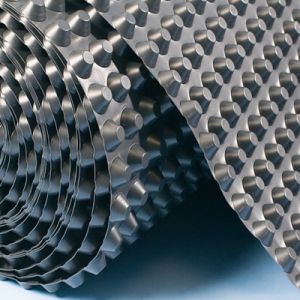

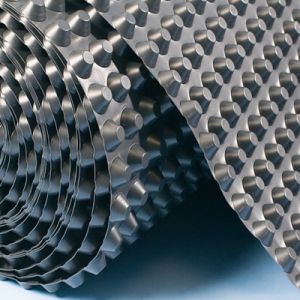

We are a reputed manufacturer of HDPE plastic dimpled drainage sheet manufacturing machines, or the Automatic Plastic Dimpled Drainage Sheet Extrusion Machine. Our equipment is designed to provide high performance and uniform output with complete automation. It is fabricated to cater to the increasing demand for dimpled waterproof drainage boards, cable protection sheets, and other plastic sheeting systems employed in civil engineering and construction.

Advantages of HDPE Plastic Dimpled Drainage Sheets

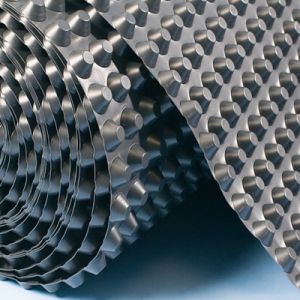

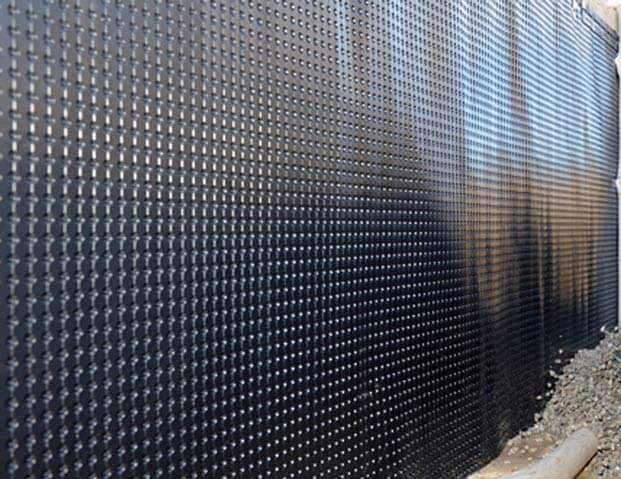

Our drainage sheets are extensively utilized in waterproofing and protection of foundation owing to the exceptional characteristics of HDPE (High-Density Polyethylene) materials. The sheets provide excellent chemical resistance, mechanical stability, and robustness.

1. Highly efficient water drainage and conductivity

The special hollow dimple structure rapidly drains water off the surface, thereby efficiently lowering hydrostatic pressure on waterproof coatings. This active hydraulic conductivity is better drainage performance with the appropriate application in underground basements, tunnels, and rooftops.

2. Durable Waterproofing

HDPE materials are inherently water-repellent. When combined with our accurate manufacturing process, the Plastic Dimple Drainage Sheet or Board serves as a strong secondary waterproofing barrier, reducing the likelihood of water intrusion.

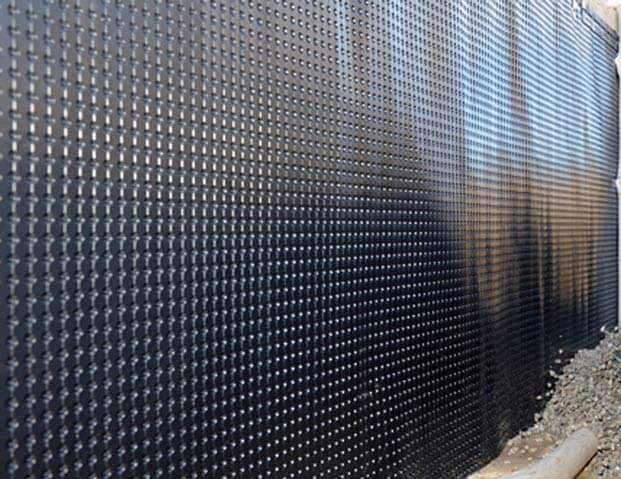

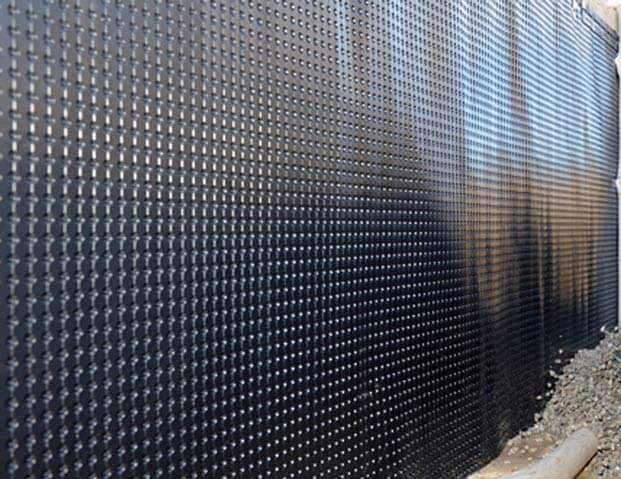

3. Structural Protection

These sheets protect the waterproofing membrane and the underlying structure from mechanical abrasion, aggressive soil pH, and invasive root intrusion. Applied to retaining walls or below-grade foundations, the sheets also provide a protective barrier against environmental and structural hazards.

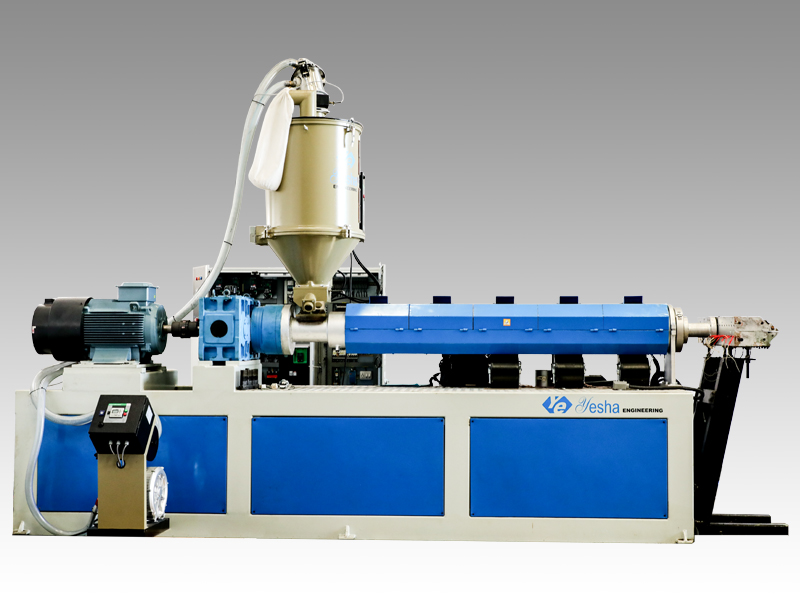

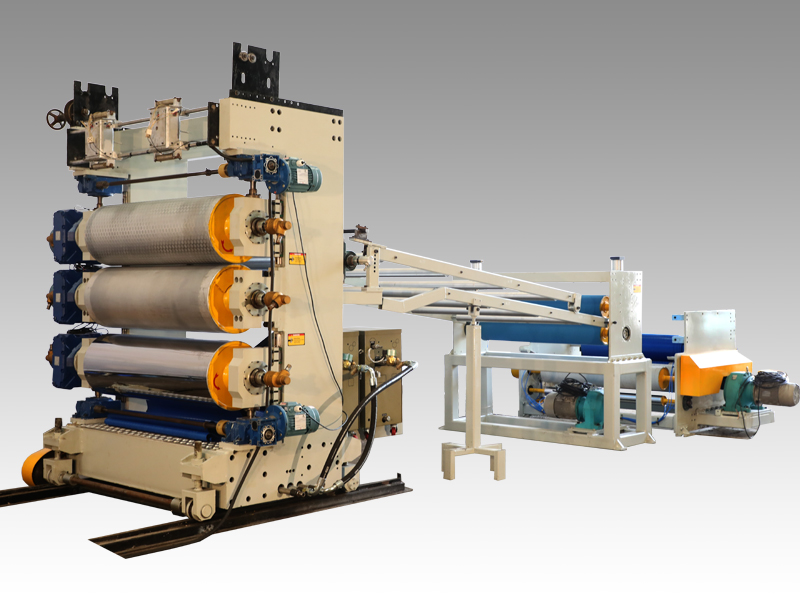

High-Quality Cable Title Extrusion Machine for Contemporary Manufacturing

Our cable title extrusion machine is a state-of-the-art extrusion system that facilitates accurate manufacturing of HDPE-based drainage and cable title sheets. With precision engineering, the system accommodates various product formats, such as Plastic Dimple Drainage Sheet or Board Making Machine, to ensure great waterproofing, mechanical protection, and drainage performance in diverse infrastructure and cabling applications.

Our plant integrates state-of-the-art Drainage Sheet Extrusion Line technology with smart control systems to provide for quick, steady, and error-free production. It is perfect for producing high volumes of uniform, robust sheets which can be tailored to various thicknesses and dimple heights.

Machine Features – HDPE Plastic Dimpled Drainage Sheet Extrusion Machine

Flexible Production

The drainage sheet extrusion machine is capable of creating different dimpled drainage sheets in various colors and sizes. The dimple heights may vary between 6mm, 10mm, 15mm, and 20mm or can be tailored as per the client’s demands.

Automatic Operation

This machine is designed as a total automation system and thus minimizes manual intervention while maximizing throughput. With a built-in smart PLC control system, the process becomes intuitive, and errors are minimized.

Multiple Molds Compatibility

Exchangable molds provide simple switching between product sizes and types. This provides manufacturing flexibility, either for use in cable title sheathing, construction drainage sheet, or for pipe wrapping purposes.

High Output & Energy Efficiency

Our drainage sheet extrusion machine is engineered for consistent high-speed output, and energy-efficient features guarantee low power usage when in continuous use.

Technical Specification

| Model | – | PSB-2000 | PSB-3000 | PSB-4000 | PSB-5000 |

|---|---|---|---|---|---|

| Screw dia. | mm | 135 | 150 | 180 | 150×2 |

| L/D ratio | L/D | 30:1 | 30:1 | 30:1 | 30:1 |

| Product width | mm | 2000 | 3000 | 4000/h | 5000 |

| Product height | mm | 8, 10, 12, 15, 18, 20, 25, 30, 35, 40 | |||

| Output | Kg/h | 400 | 500 | 700 | 1000 |

| Line speed | m/min | 2-6 | |||

| Installed capacity | KW | 252 | 320 | 410 | 550 |

| Power consumption | KW | 132 | 160 | 220 | 300 |

| Dimensions (L×W×H) | m | 22x4x2.8 | 22x5x2.8 | 22x6x2.8 | 22x6x2.8 |

| Total weight | T | 16 | 20 | 28 | 35 |

Uses of Dimpled Drainage Sheets and Cable Title Extrusion

Our cable title extrusion machine and drainage sheet extrusion lines are best suited for producing sheets that are utilized in:

- Civil construction (basements, tunnels, retaining walls)

- Underground cabling and pipe protection

- Road and rail projects

- Landscaping and green roofs

- Bridge deck waterproofing

These multi-purpose uses are made possible by the toughness, flexural strength, and ability of our HDPE sheets to withstand stress, and the accuracy with which they’re manufactured by our Plastic Pipe Machine and associated extrusion systems.

Why Choose Our Extrusion Machines?

Latest Technology: We employ the latest methods to provide the best dimensional stability and surface finish.

- Customizable Outputs: For any particular sheet size or dimple arrangement, our machines can be customized accordingly.

- Dependable Automation: With our automated Drainage Sheet Extrusion Line driven by high-performance PLC systems, save time and labor expenses.

- After-Sales Support: We provide installation support, technical training, and 24/7 assistance to keep your production line functioning well.

Get in Touch

Maximize your manufacturing productivity with our Cable Title Extrusion Machine and Drainage Sheet Extrusion Line systems. Whether you work in construction, infrastructure, or cable manufacturing, we have the ideal solution through modern automation and stable output.

Reach us today for a tailored quote or further technical information regarding our machines.

FAQs

Q1. What is a cable title extrusion machine?

A cable title extrusion machine is a dedicated machine employed to produce plastic covers or sheets that waterproof cables, defend against pressure, and mechanical abrasion. It is commonly employed in subterranean cable installations.

Q2. Is the machine applicable to plastic pipe or cable sheathing?

Yes, it supports various mold heads and can be modified to make parts associated with Plastic Pipe Machine manufacturing and cable sheathing.

Q3. What materials are compatible with this extrusion line?

Our machine is designed primarily for HDPE, but can also work with LDPE and other thermoplastic polymers depending on the sheet specifications required.

Q4. What is the maximum dimple height the machine can produce?

The machine supports dimple heights of 6mm to 20mm. Custom specifications can be designed on request.

Q5. Is this a fully automatic system?

Yes, it is an Automatic Plastic Dimpled Drainage Sheet Extrusion Machine with PLC control for automatic feeding, extrusion, cooling, molding, and cutting operations.

Q6. Do you have installation and training services?

Yes, certainly. We deliver thorough training to your personnel and complete support during the course of installation.

Q7. What are plastic dimple drainage sheets commonly used for?

These sheets have broad applications in foundation waterproofing, protection of retaining walls, green roofs, drainage layers, and as cable title layers in infrastructural projects.