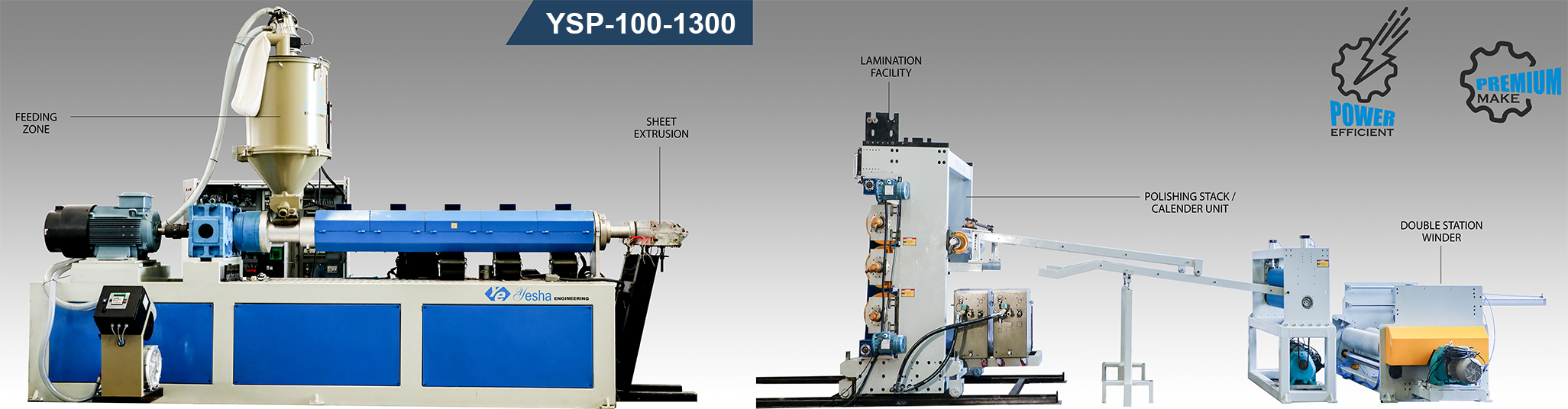

Advanced PVC Anti Skid Mat Extrusion Machine & Electric Insulating Mat Extrusion Machine

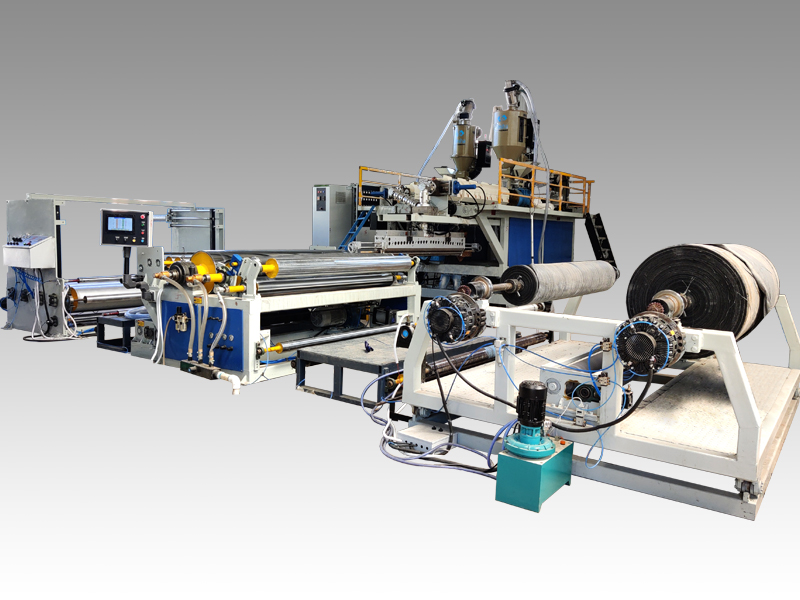

Yesha Extrusion Machineries introduces cutting-edge solutions to fulfill your industrial floor requirements with our advanced PVC anti skid mat extrusion machine and electric insulating mat extrusion machine. Composed of superior technology and long-lasting materials, these machines provide smooth, even, and effective mat production for commercial, electrical, and safety uses.

Whether you’re producing anti-skid safety floor mats for public areas or electrical insulation rubber matting for industrial applications, our extrusion lines provide outstanding results with low maintenance.

Why Our PVC Anti Skid Mat Extrusion Machine Excels

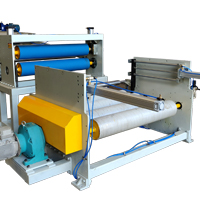

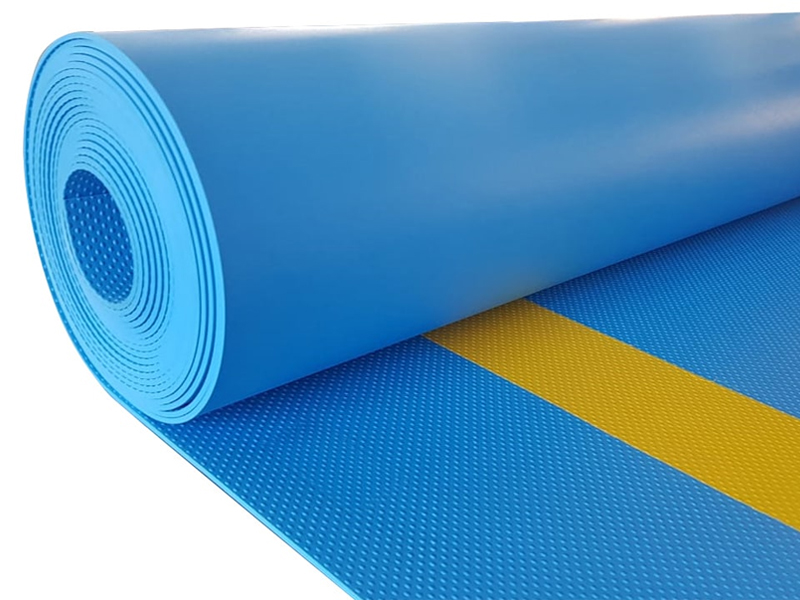

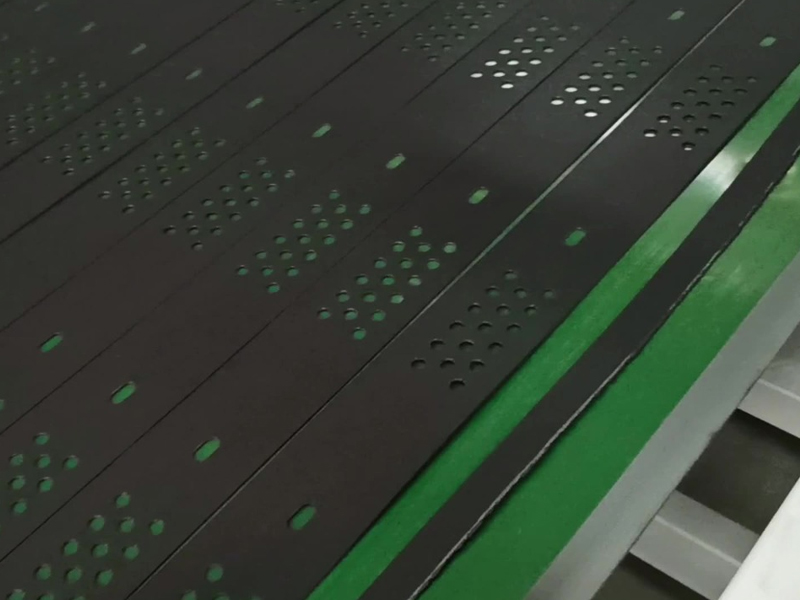

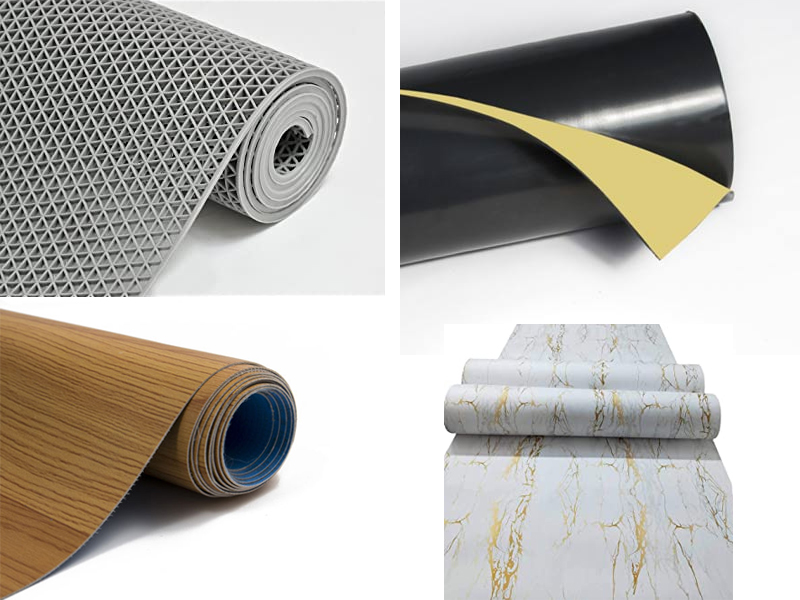

The PVC anti-skid mat extrusion machine is designed for high-speed production and precision calendaring. It produces textured, anti-slip mats in varied patterns such as diamond, tooth, strip, and dot patterns that have a firm grip and cushioning for better safety.

- Uses: Door mats, car floor mats, bathroom mats, hotel lobbies, airports, restaurants, and public utilities.

- Material: High-grade PVC granules

- Mat Properties: Resistance to acid and alkali, UV stability, and heat endurance (high and low temperatures)

As being a part of the PVC Insulating Floor Matt Extrusion Line, this system provides high productivity and flexibility in creating custom surface textures conforming to exact safety and design specifications.

Solid Electric Insulating Mat Extrusion Machine for Industrial Protection

Our extrusion machine is ideal for Safety Floor Mats for Electrical Insulation Purposes. These mats are essential in avoiding electric shocks in high-voltage areas and are extensively applied throughout industrial buildings, substations, and power plants.

- Dielectric Properties: High insulation resistance

- Surface Finish: Even, textured surface with ideal gauge control

- Output: 300–350 kg/h

- Widths Available: Up to 2000mm

- Thickness: 0.5mm to 3mm

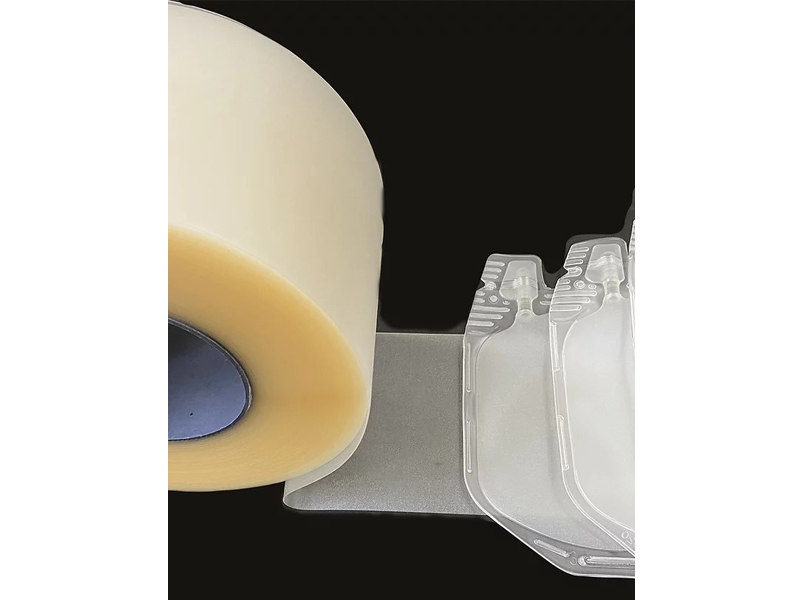

The line includes features such as precision lamination, film coating, and double-station winding to deliver the best performance and effective post-extrusion processing.

Technical Features

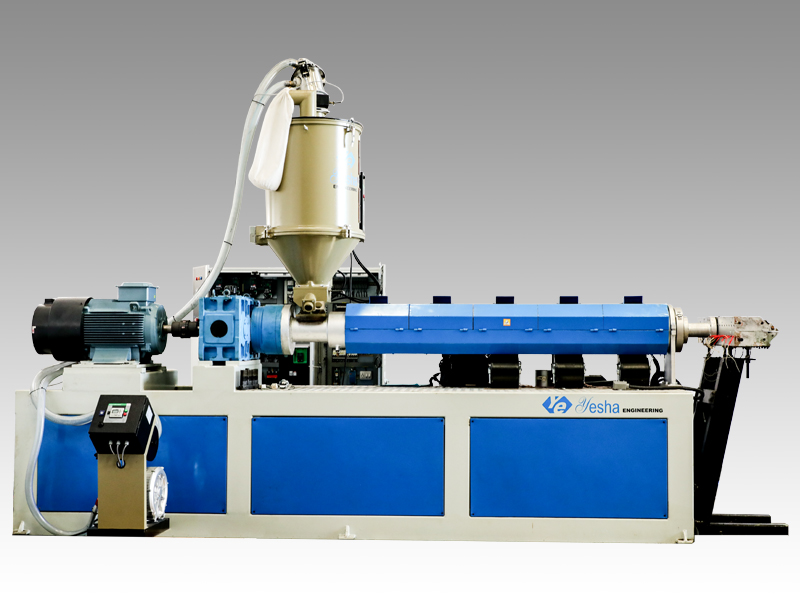

- Feeding & Drying Zone: Automatic hopper loader and 24×7 production dryer

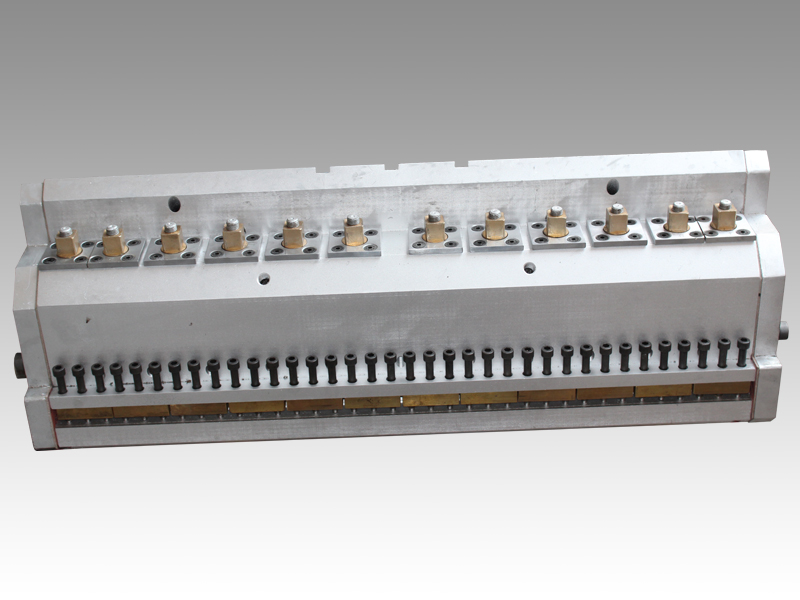

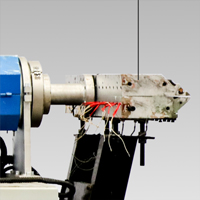

- Extrusion System: Unique screw & barrel design for consistent melt and stable flow

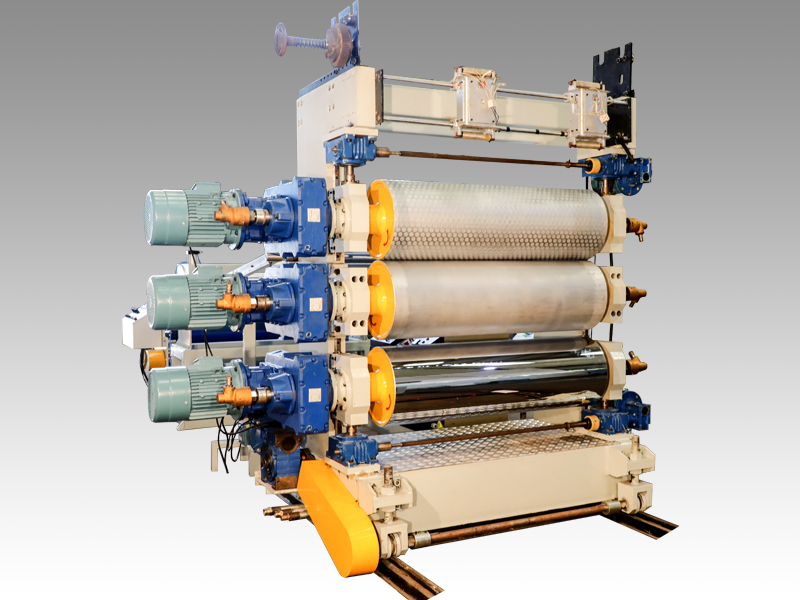

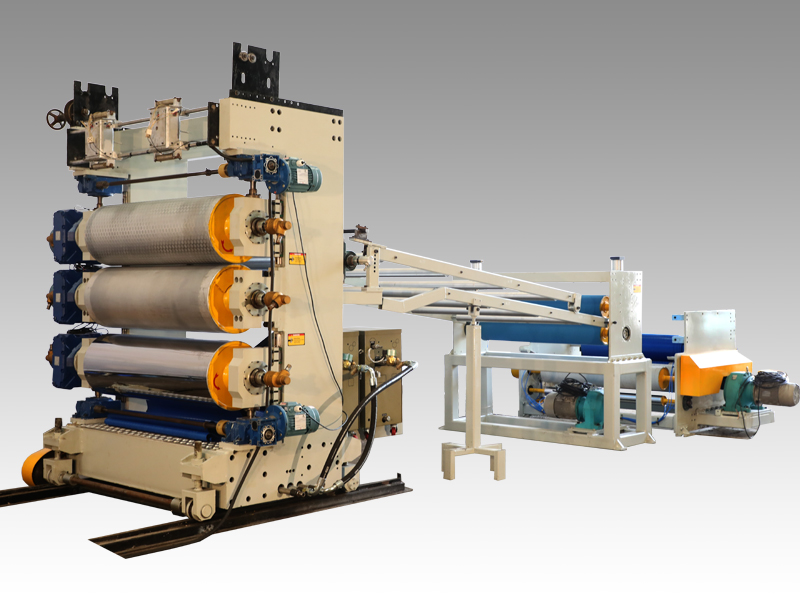

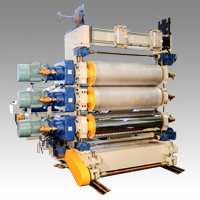

- Calender Unit: Provides consistent sheet thickness and textures application

- Lamination System: Adhesive coating, branding, or fabric layering as optional features

- Cooling & Haul-Off: Fast cooling system and silicon rubber rolls for smooth pulling

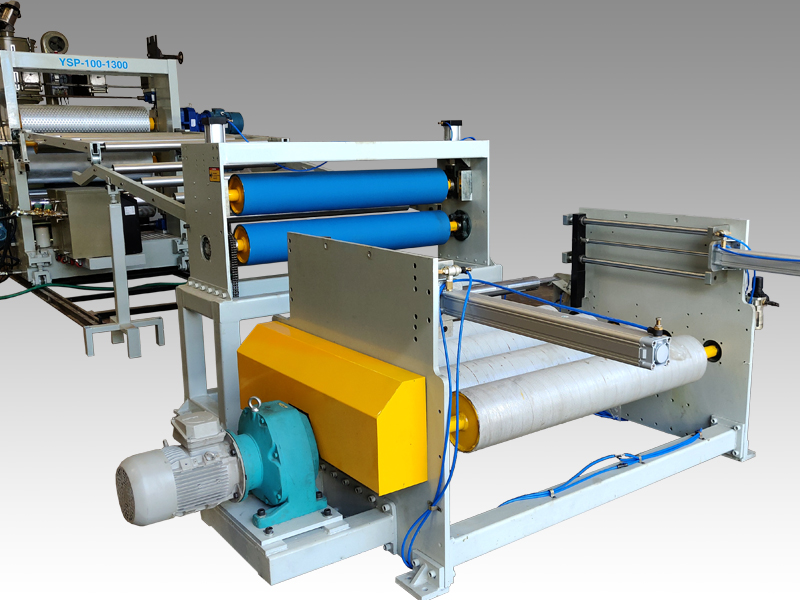

- Winder: Dual-station winding with auto-cutting and PLC control

The line also accommodates manufacturing for PVC S Mat Anti-Slip Mat Extruder Making Machine models for high-speed, single-layer mat production.

Production Process at a Glance

- PVC Granules Mixing

- Automatic Extruder Feeding

- Melting & Filtering

- Die Extrusion

- Calendering / Texture Forming

- Lamination

- Cooling Frame

- Trimming & Pulling

- Metering & Winding

Industries We Serve

- Commercial Flooring & Interiors

- Electrical Safety & High-Voltage Equipment Areas

- Construction and Insulation

- Decorative Film & Surface Protection

- Infrastructure & Industrial Designations

In whatever volume and quality you produce, whether it is textured commercial mats or electric insulation rubber matting, our machines conform to your volume and quality requirements.

Achieve the Perfect Edge with Yesha Extrusion Machinery

Invest in high performance, precision, and durability with our electric insulating mat extrusion machine and PVC anti skid mat extrusion machine. Designed to meet contemporary industrial needs, our extrusion lines enable your business to manufacture safety-approved, high-quality mats with ease.

Reach out to us today to receive a tailored quote or learn more about incorporating our solutions into your production line.

FAQs

- What is the major application of a PVC anti-skid mat extrusion machine?

It is employed to produce PVC textured anti-slip floor mats from PVC granules. Such mats are generally installed in commercial areas, vehicles, and public entrances to avoid slipping and improve safety.

- Where is the electric insulating mat extrusion machine generally employed?

It is employed to manufacture electrical insulation mats, primarily in substations, switchgear rooms, and industrial sites, for protecting workers against electrical risks.

- What is the output capacity of these machines?

Both machines produce an output of about 300–350 kg/h, based on the configuration and material utilized.

- Is the machine capable of manufacturing mats with special surface designs?

Yes, the unit calendar provides the facility for making different back patterns such as dots, stripes, diamond shapes, etc., as part of our PVC S Mat Anti-Slip Mat Extruder Making Machine series.

- Can these machines be used for multi-layer mat production?

Yes, certainly. The extrusion machine features a lamination unit to provide layering with fabrics, foams, or logo films, ideal for branding or additional functional layers.

Features

We provide Hopper loader-feeder & dryer for round-the-clock production with less men power.

Our precise manufacturing & supreme quality gets effective control over mold for smooth production.

This mechanism is provided for coating addisive layer of sheet/Texture/protection/logo etc.

Finishing product & textured design is embossed from this unit , Also to maintain uniform gauge of sheet.

This unit is equipped with AI to cut length given in PLC & to wind the sheet, dual station facility for smooth operations.

Two super finish silicon-rubber roll are used to pull the sheet/

Solution For Extrusion IndustryWe believe in Quality

Commercial floorings, Waterproofing, Insulation/isolation, Surface Protection, Decorative films, High barrier sheets, Roofing/wall body, Construction material.

Key Features

- Commercial Floorings

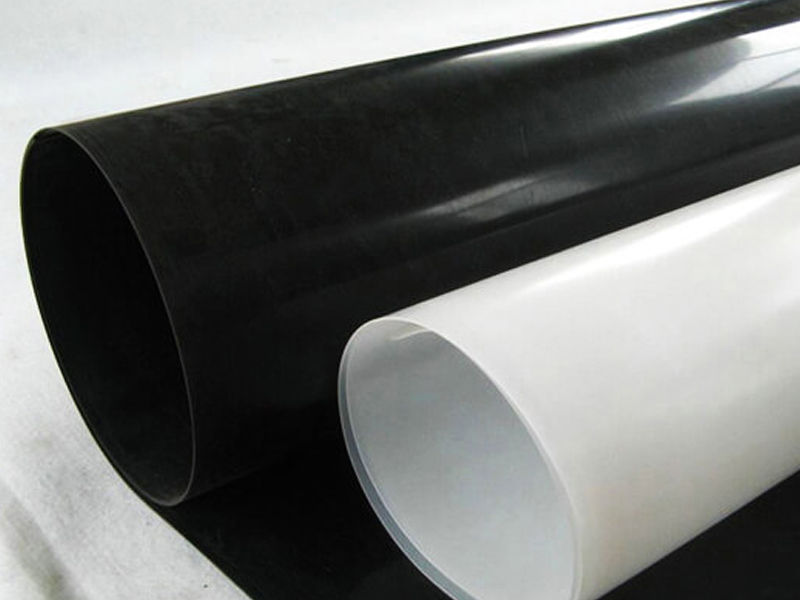

- Waterproofing

- Insulation/isolation

- Surface Protection

- Decorative films

- High barrier sheets

- Roofing/wall body

- Construction material

Our Clientele