Take Your Production to the Next Level with a PVC LVT Flooring Production Machine

Looking to expand your flooring business? Yesha Engineering’s advanced PVC LVT flooring production machines are built to boost your efficiency, reduce costs, and consistently deliver premium quality results. Whether you’re upgrading your current line or starting a new venture, our cutting-edge technology will give you a competitive edge in the fast-growing flooring market.

Reasons to Choose a PVC LVT Flooring Production Machine

These factors have influenced the demand for PVC LVT (Luxury Vinyl Tile) to become a common flooring choice in both residential and commercial construction. The durability, design, and affordability of PVC LVT are features that many consumers prefer. The demand for PVC LVT is growing, and as a result, manufacturers are in need of a high-output LVT flooring extrusion machine that offers performance, customization, and speed.

At Yesha Engineering, our LVT Flooring Production line integrates state-of-the-art technology to help manufacturers meet these goals.

With our production machine, you can achieve:

- Increased production capacity

- Lower labor costs via automation

- Superior quality control

- Flexibility in design, size, and thickness

Key Features

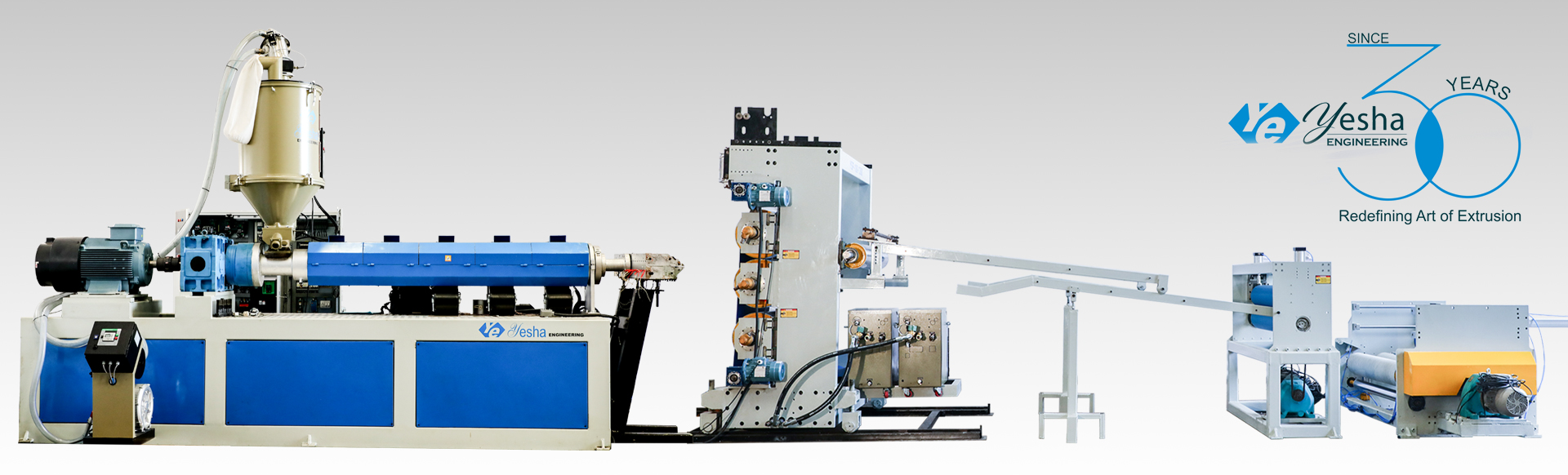

Completely Automated PVC LVT/WPC Plastic Floor Production Line

Maximize productivity with automation. Our Automatic PVC LVT WPC Plastic Floor Production Line machine minimizes manual operations while streamlining material mixing, extrusion, lamination, cutting, and stacking.

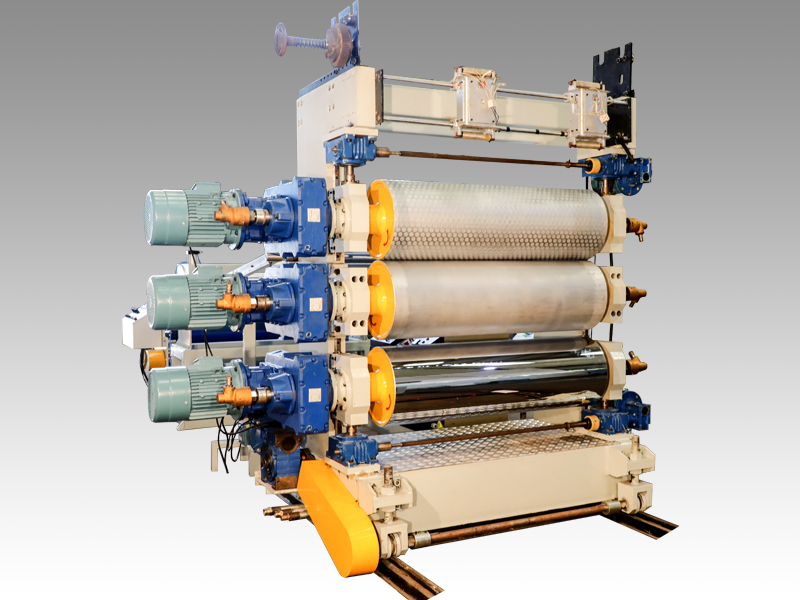

High Precision Extrusion System

The Sheet Extrusion Line ensures uniform thickness and optimal density, boosting the strength, durability, and finish of every flooring tile.

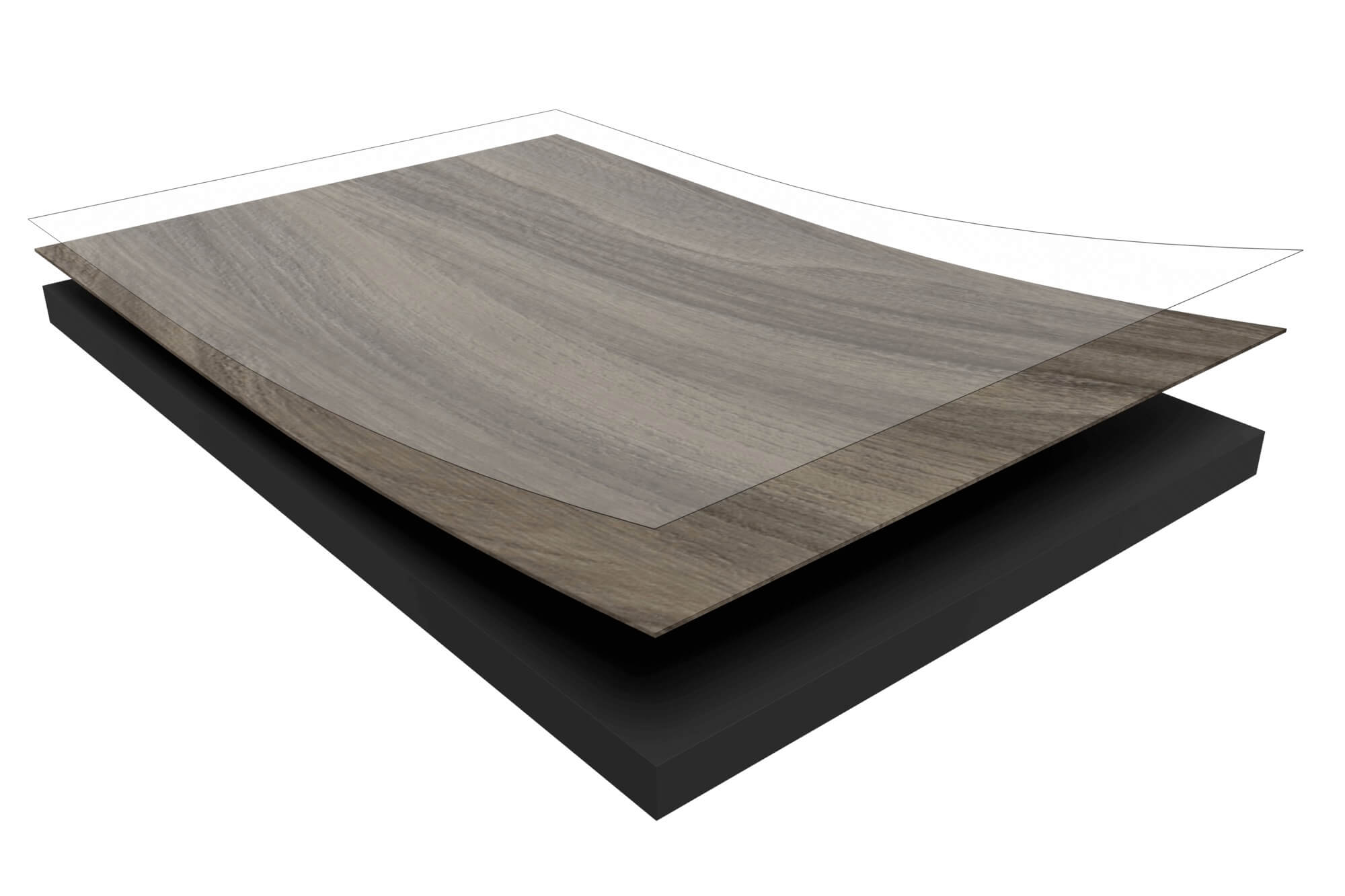

Multi-Layer Lamination

Our LVT Flooring Extrusion Line supports multi-layer lamination, enabling authentic wood grain or stone pattern effects that add premium appeal.

PVC Carpet Back Coating Machine

We also offer a PVC carpet back coating machine, which compounds plastic onto the carpet’s backing. This enhances waterproof performance and extends the carpet’s lifespan. The machine performs lamination, spinning, and forming into dual-layer carpets through a fully automated process.

User-Friendly Operation

With an intuitive interface and intelligent diagnostic systems, the machine is easy to operate even for new operators.

Customizable Output

Easily adjust production settings to meet varying customer demands, whether it’s plank dimensions, design patterns, or thickness.

What Sets Our LVT Flooring Apart?

Our YESHA 3-Layer Glue-Down Commercial-Grade Vinyl Flooring is crafted using advanced layering technology for optimal performance:

- BACKING LAYER: Constructed with three individual layers, each rotated for maximum interlocking strength. Fused with a hot press system for added durability.

- PRINT DESIGN LAYER: A photographic film design replicates vibrant, realistic textures like hardwood or stone.

- WEAR LAYER: A durable top coating protects against scratches, wear, and fading ideal for high-traffic areas.

Advantages of Our LVT Production Solutions

- Boost Production Efficiency

Shorten production cycles and meet high-volume orders without compromising quality.

- Reduce Operational Costs

Automated systems reduce the need for manual labor and lower material waste.

- Elevate Product Quality

Advanced extrusion and lamination technologies ensure flawless finish and strength.

- Expand Product Range

Produce a wide array of styles, textures, and sizes to meet diverse customer preferences.

- Environmentally Conscious

Optimized raw material use and energy-efficient systems make our lines eco-friendly.

Complete PVC LVT Vinyl Flooring Production Line

To maximize performance, we offer a comprehensive production solution that includes:

- Raw material feeding systems

- Precision mixing and extrusion units

- Calendering and multi-layer lamination systems

- High-speed cutting and stacking equipment

- Final-stage inspection and packaging lines

This turnkey setup enables you to go from PVC granules to finished luxury vinyl tiles in a smooth, uninterrupted process.

Choosing the Right Machine for Your Needs

Before you invest, consider:

- Your production capacity requirements

- Tile types and finishes you want to produce

- Space availability and layout

- Budget and ROI expectations

- After-sales support availability

Yesha Engineering works closely with you to deliver tailored production solutions that match your operational goals.

Automated Automatic PVC LVT WPC Plastic Floor Production Line for Next-Gen Manufacturing

Our versatile production line can manufacture both PVC and WPC flooring. Key benefits include:

- High-level automation

- Reduced errors and manual labor

- Seamless switching between styles

- High-speed, high-volume output

- Capability to serve residential, commercial, and industrial markets

Conclusion

Take your flooring production to the next level with Yesha Engineering’s PVC LVT flooring production machine and flooring production line. By combining modern automation, multi-layer customization, and exceptional build quality, we help you produce premium luxury vinyl flooring that meets today’s market demands.

Contact us today to learn more about how our solutions can enhance your productivity and profitability.

FAQ

- What is a PVC LVT flooring production machine?

It’s a specialized machine used to manufacture luxury vinyl tiles (LVT) from PVC. It automates key steps such as extrusion, lamination, cutting, embossing, and stacking to ensure consistent, high-quality output.

- How does this machine improve production efficiency?

By automating major processes and reducing human error, it significantly shortens production times and boosts product consistency.

- Can the machine produce multiple designs and tile sizes?

Yes. The system is engineered for multi-layer lamination and print customization, allowing varied tile textures, sizes, and styles.

- What’s the difference between WPC and PVC flooring in the line?

PVC flooring is made purely from polyvinyl chloride, while WPC flooring combines PVC with wood fibers, offering added rigidity and a wood-like appearance. Our machine supports both.

- Why choose Yesha Engineering?

We offer cutting-edge technology, custom-configured systems, and robust after-sales service, helping you scale your business efficiently.

Our Clientele