Artificial Marble Sheet Extrusion Machine for High-Quality Manufacturing

With increasing demand for fashionable, long-lasting, and affordable interior wall covering materials, PVC artificial marble sheets are gaining popularity. These man-made equivalents of natural stone provide unprecedented aesthetic appeal, performance, and flexibility. To cater to the growing demand, manufacturers are looking toward the artificial marble sheet extrusion machine, an advanced production line that integrates state-of-the-art technology with maximum efficiency.

Our PVC UV Coated Marble Sheet Extrusion Line is specially designed to deliver high-gloss, fire-resistant, and water-resistant marble-effect sheets. It’s the perfect investment for companies seeking to expand production without diluting quality.

What is an Artificial Marble Sheet Extrusion Machine?

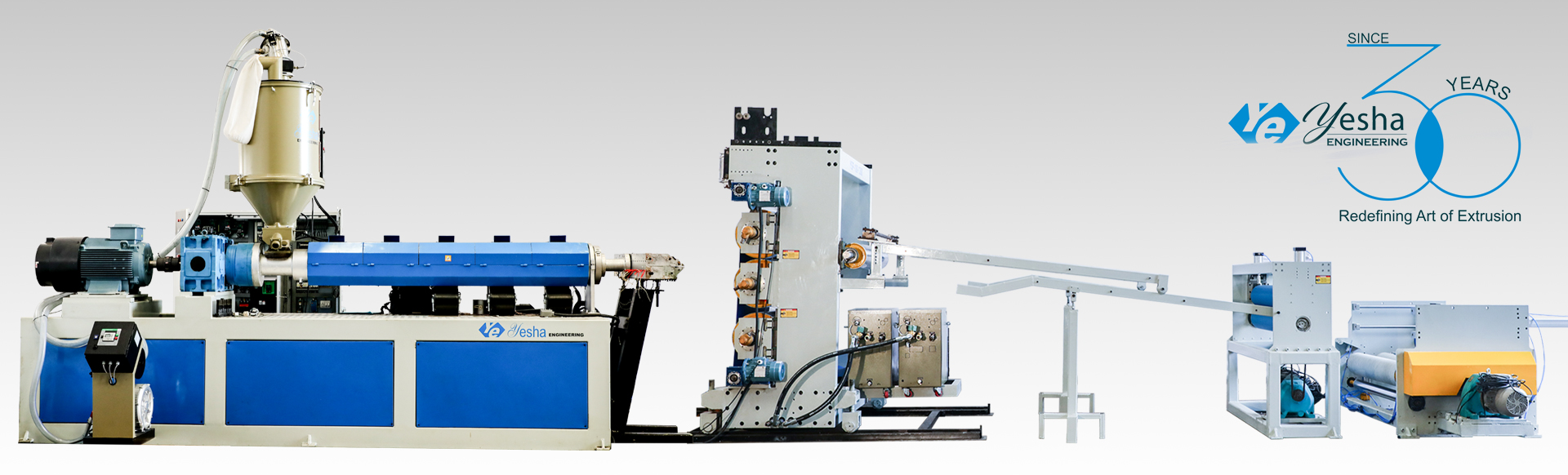

An artificial marble sheet extrusion machine is a full production line that processes PVC and other raw materials into sheets that mimic the appearance and feel of natural marble. It entails material mixing, extrusion, calendering, UV coating, and final curing. The result is a lightweight, durable, and beautiful marble sheet for use in many interior decoration needs.

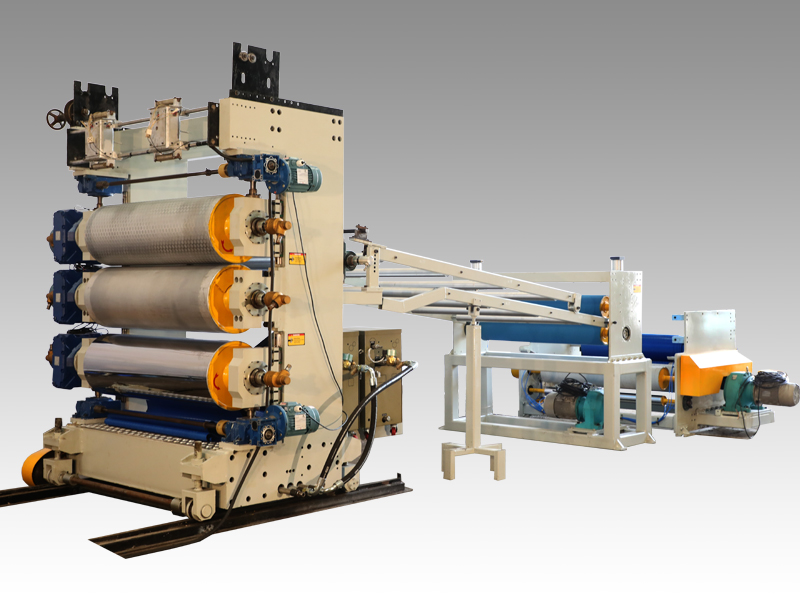

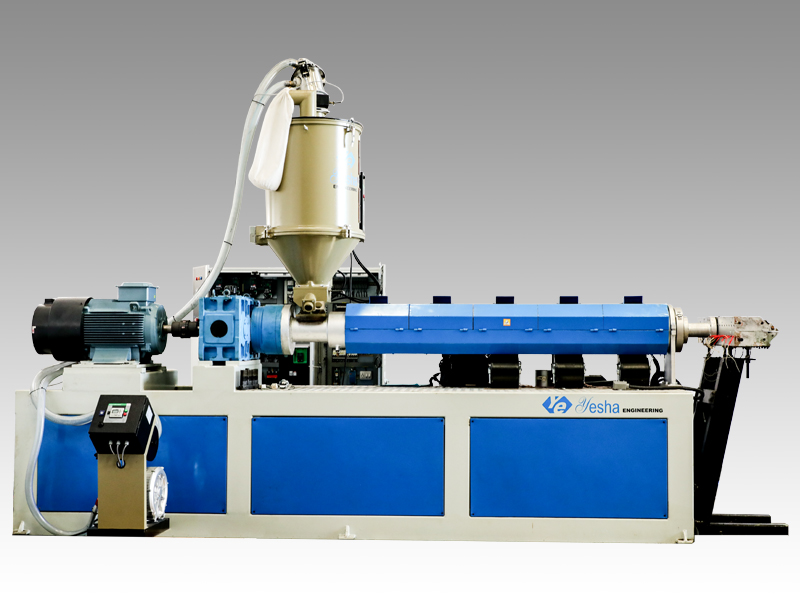

This state-of-the-art extrusion line features a PVC Marble Sheet Extruder machine, twin-screw extruder, T-die, calendering units, cooling and traction systems, UV coating units, cutting machines, and stackers, all harmonizing together to achieve maximum productivity and quality.

Key Features of Our PVC Artificial Marble Sheet / Board Production Line

Our PVC artificial marble sheet production line features high-tech components that are specifically made for optimal operational efficiency and product uniformity. Here is a closer inspection of what makes our system unique:

High Precision & Automation

The extrusion process of our machine ensures a uniform sheet thickness and a smooth surface finish that is smooth. The equipment comes with smart temperature controls, variable frequency drives, and coordinated motor systems for precise manufacturing.

High-Temperature Resistance with UV Coating

Every sheet is treated with a UV coating process that gives it a high-gloss finish, scratch-proof, and long-lasting toughness. The UV imitation marble board:

- Is scratch and ageing resistant

- Has better anti-yellow and UV resistance

- Represents natural marble appearance with no radiation harm

- It is available in a wide range of designs and colors

Energy Efficiency

The extrusion machine is constructed with energy-saving materials, cutting costs of operation while offering high-output volume. Our PVC marble sheet machine guarantees minimal wastage of materials and efficient heat distribution.

Technical Specifications

Specification | Detail |

Maximum Sheet Width | 1220 mm |

Sheet Thickness Range | 2 mm to 8 mm |

Production Capacity | 350 kg/hr |

Total Equipment Weight | Approx 20 tonnes |

Material | PVC witg UV Coating |

Application | Interior Wall Panels, Partitions |

Advantages of Utilizing Artificial Marble Sheet Extrusion Machine

Investing in our artificial marble sheet extrusion machine comes with several benefits, enhancing your production efficiency, decreasing costs, and increasing end-product quality.

Diverse Applications

These sheets can be applied in various applications, such as:

- Wall paneling for residences and offices

- Ceiling ornaments

- Hotel lobbies and conference rooms

- Kitchen and bathroom interior decor

- Elevator panels and business establishments

Excellent Aesthetic Appeal

With the help of the PVC artificial marble sheet/board manufacturing line, you can produce sheets that are virtually indistinguishable from natural marble, in various textures and colors.

Durable and Resistant

Manufactured sheets are:

- Waterproof and fire-resistant

- Anti-scratch and anti-aging

- UV ray and discoloration resistant

Eco-Friendly Substitute

PVC-marble sheets are non-toxic, radiation-free, and eco-friendly as compared to naturally mined stone.

Simple Maintenance and Installation

In contrast to actual marble, PVC marble sheets are light in weight, transportable, easy to cut, and install, the contractor’s dream.

Complete System Components

PVC marble sheet machine consists of:

- Mixing Unit: Mixes PVC resin, calcium carbonate, additives, and stabilizers for the uniform blend.

- Twin-Screw Extruder: Provides homogeneous melt flow and effective material extrusion.

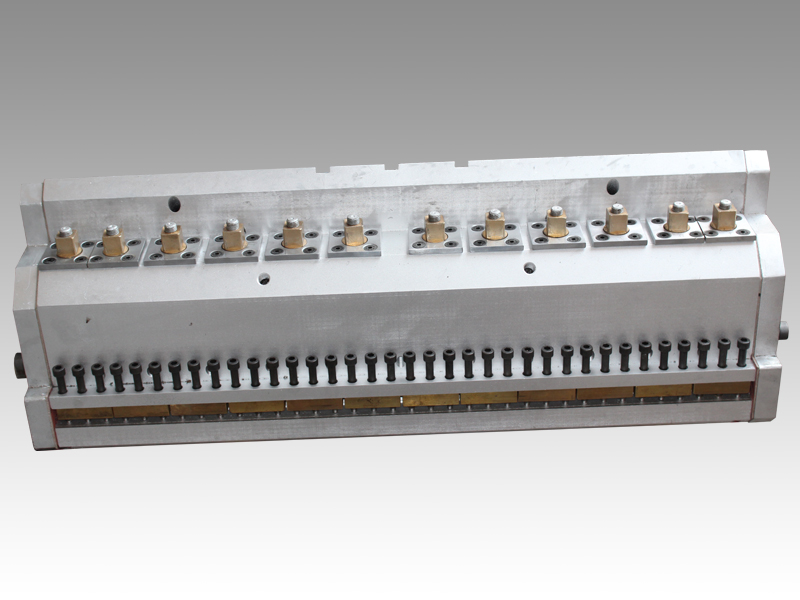

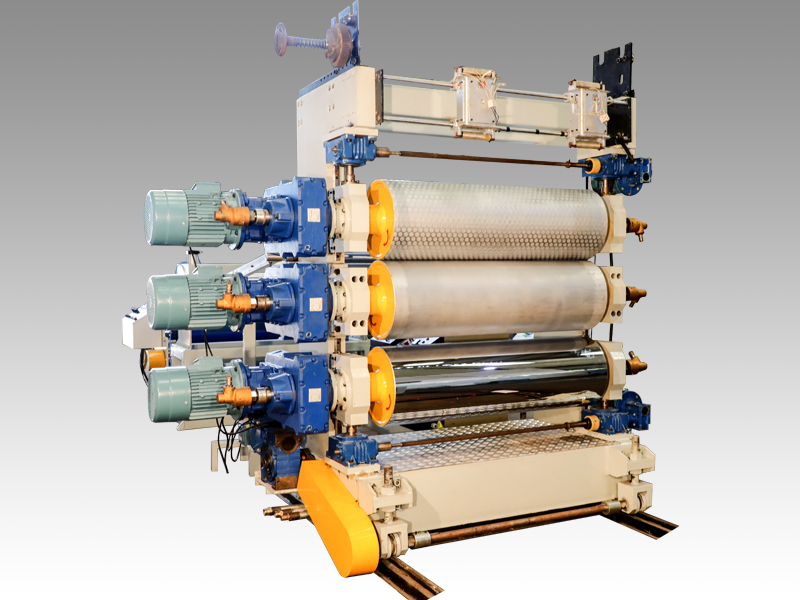

- T-Die & Calendering Unit: Forms the sheet and polishes the surface.

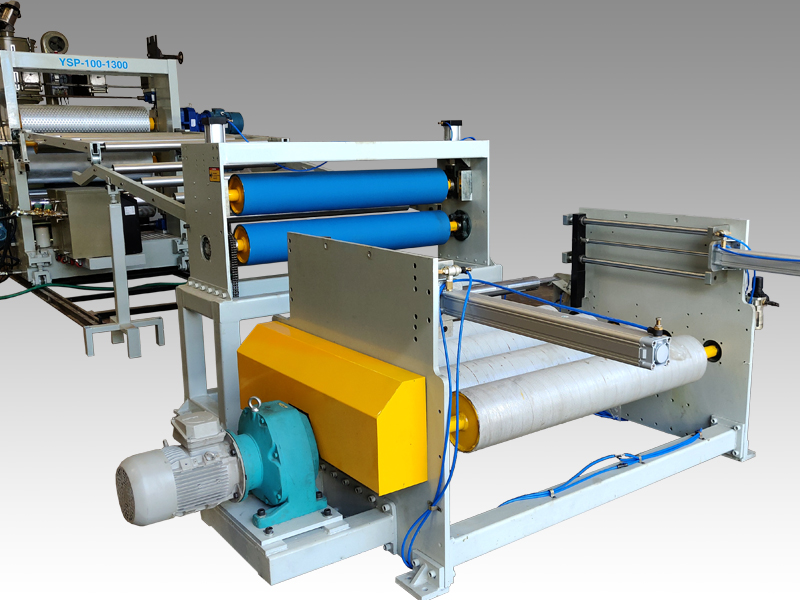

- Cooling System: Quick cooling for dimensional stability.

- UV Coating and Curing Line: Gives shine and durability.

- Cutter & Stacker: Automatic sheet cutting and stacking for end output.

This production line is modular in nature, hence, it can be tailored according to your specific requirements and factory configuration.

Applications

The end sheets find vast application in:

- Commercial complexes

- Shopping malls

- Hotels and resorts

- Modular kitchen and bathroom configurations

- Public infrastructure and interior renovation works

Final Thoughts

If you need to up your production capacity with robust, sophisticated, and convenient interior wall solutions, our PVC Marble Sheet Machine machine is the perfect investment. It’s highly performative, automated, and flexible, enabling you to make high-quality PVC artificial marble sheets that pass both aesthetic and functional expectations.

With high output, low maintenance, and scalable design, our PVC marble sheet machine empowers manufacturers to stay ahead in a competitive market while reducing production costs and maximizing product value.

FAQs

- What is the purpose of a marble sheet extrusion machine?

A marble sheet extrusion machine is meant to create PVC-based marble sheets mimicking natural stone. It encompasses several processes — mixing, extrusion, calendering, and UV coating — to provide sheets employed in decorative interior wall cladding.

- What volume of material can the machine handle per hour?

Our machine has an output capacity of 350 kg/hr, fitting into high-volume production plants.

- What is the highest width and thickness accommodated by the PVC marble sheet machine?

The extrusion line accommodates a maximum sheet width of 1220 mm and thickness of 2 mm to 8 mm, encompassing a vast range of design and application needs.

- Are the sheets waterproof and fireproof?

Yes. Sheets made on our PVC artificial marble sheet/board manufacturing line are fire-resistant and waterproof, and therefore suitable for humid or hot environments such as kitchens and bathrooms.

- Must the UV coating be applied? What are its advantages?

Certainly. The UV coating improves the gloss, scratch resistance, and toughness of the sheet and also gives UV and ageing resistance, ensuring the product retains its appearance in the long term.

- Can I create multiple colors, styles, and designs with this machine?

Yes. The system accommodates numerous decorative films and laminators so that you can create a vast array of styles, textures, and colors that mimic various forms of natural marble.

- How green is the sheet that is created?

The PVC UV-coated marble sheet is green, with no toxic chemicals or radiation. It’s recyclable too and a sustainable alternative to mined marble.

Our Clientele